Introduction of Automatic Filter Presses

Automatic Filter Presses represent a pinnacle in filtration technology, designed to streamline and optimize solid-liquid separation processes across various industries. These advanced systems are pivotal in achieving high-efficiency filtration while minimizing operational costs.

Fully Automatic Filter Press Composition:

1.Thrust Plates 2. Membrane Plates

3. Chamber Plates 4. Middle Support

5. Main Beam 6. Hydraulic Station

7. Washing Filter Cloth Rack 8. Filter Plate Handle

9. Belt Conveyor 10. Pull Plate Trolley

11.Washing Lifting Motor 12. Guide Hopper

13. Drip Tray

Applications of Automatic Filter Press:

1.Wastewater Treatment:

Automatic chamber filter presses are widely used in wastewater treatment, effectively removing suspended solids to reduce sludge volume and improve water quality. This type of filter press machine allows for efficient dewatering, producing drier sludge that is easier and less costly to dispose of.

2.Chemical Processing:

In the chemical industry, these automated filter presses are used to separate valuable products from waste streams. The precise control over pressure and filtration parameters ensures the recovery of high-purity products while minimizing waste.

3.Mining and Mineral Processing:

Mining operations generate significant volumes of slurry that require dewatering. Fully automatic filter presses handle the demanding conditions of mining applications, providing reliable and efficient solid-liquid separation. By using Longone filter press machine, the moisture content of the filter cake can be significantly reduced to 10%.

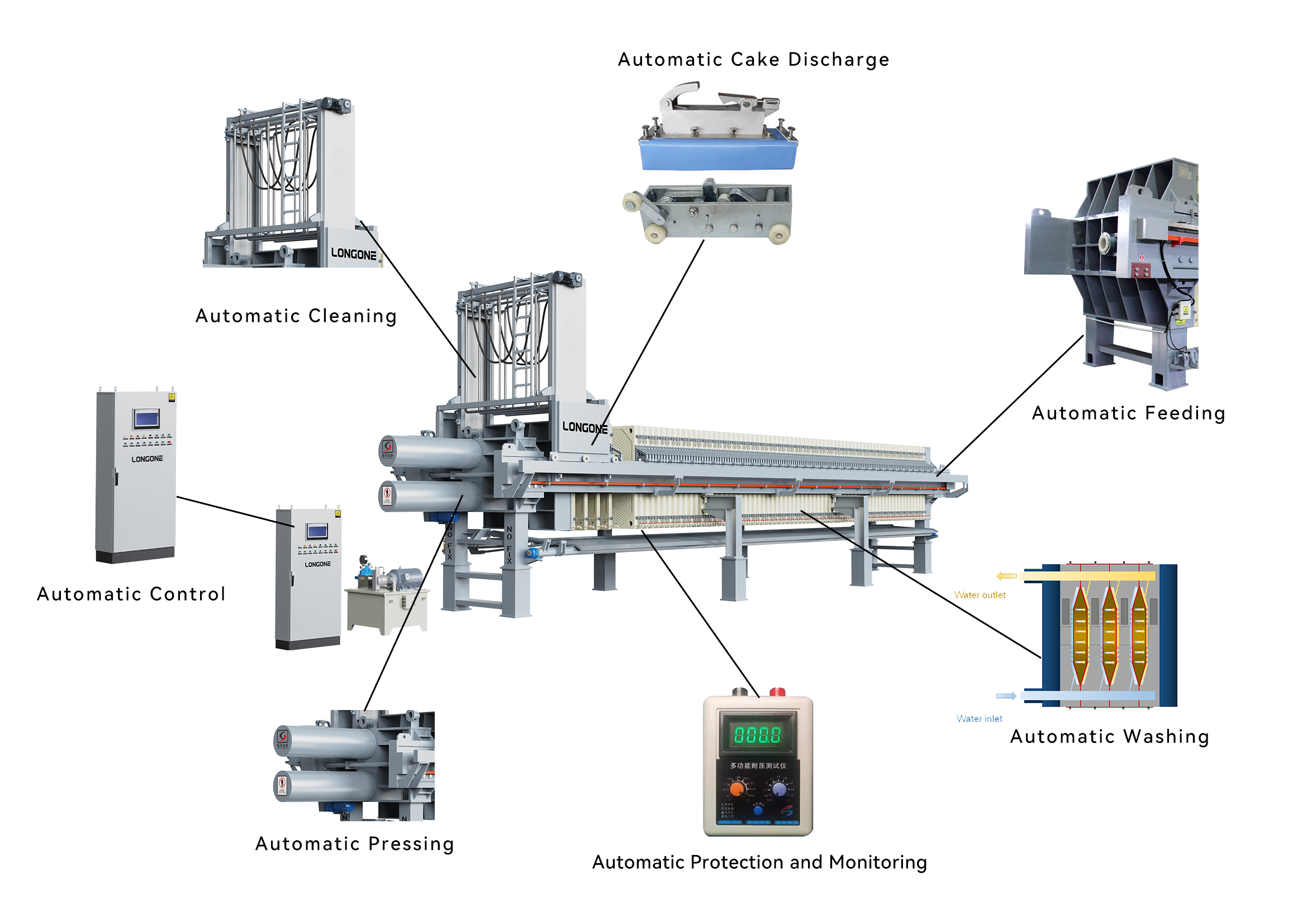

What does “Automatic” mean?

Fully automatic filter presses are characterized by their automation in several key aspects:

1.Automatic Feeding: The filter press machine automatically introduces the material into the filter chamber.

2.Automatic Pressing: Hydraulic or mechanical systems automatically press the filter plates together, applying the necessary pressure for filtration.

3.Automatic Washing: Some models of automated filter press feature automatic cake washing to wash away soluble substances from the filter cake.

4.Automatic Cake Discharge: After dewatering, the plate shift device startup, and the filter cake is automatically discharged from the plates.

5.Automatic Control: The entire filtration process is controlled by a PLC system, which manages parameters such as pressure, timing, and feed rate.

6.Automatic Protection: The automatic chamber filter press includes automatic safety features to protect against overloads and overpressure, ensuring stable operation.

7.Automatic Monitoring: the automated filter press supports remote monitoring and operation capabilities, facilitating unattended operation.

8.Automatic Cleaning: The filter cloths are automatically cleaned, reducing the need for manual maintenance.

Fully automatic filter presses enhance production efficiency and safety through automation, reduce labor intensity and operational costs, and improve the overall filtration process.

Longone Enterprise Profile:

Established in 2007, Longone Corporation specializes in providing integrated filter press filtration systems. We offers a range of services from R&D to production, installation, and after-sales support, including professional solutions tailored to customer needs. The product line includes various types of automatic filter presses, as well as a wide range of filter plates in different materials and sizes, from 250x250mm to 2500x2500mm, and pressures up to 6.0MPa. The temperature range for filtering is from -40 to 120 degrees Celsius, with filter areas from 0.16 m² to 1600 m². Longone also provides customization services for non-standard filter press machine and filter plates, accommodating special requirements.

Qualification Certificate:

Longone has obtained lSO9001 quality management system certification, CE certification and other qualification certifications.