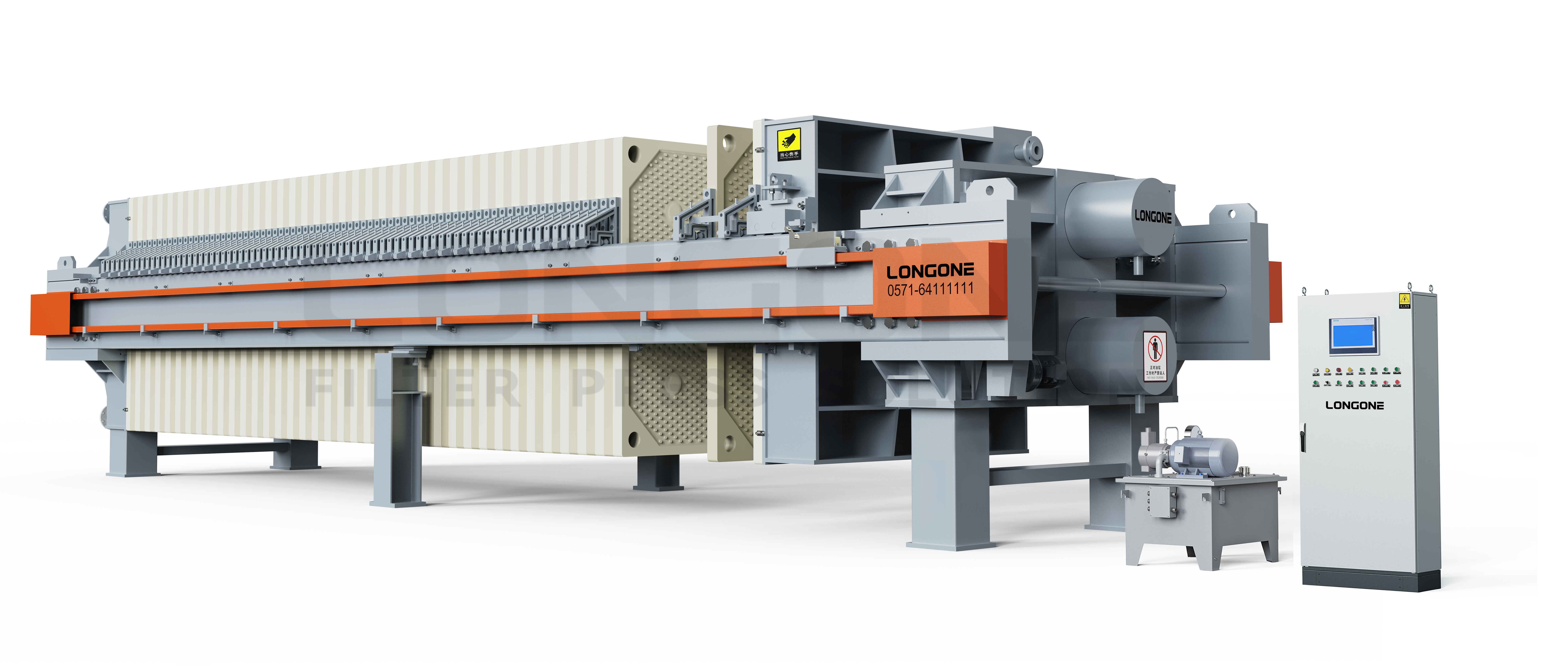

Introduction to Plate and Frame Filter Press:

The plate and frame filter press is a type of intermittent solid-liquid separation equipment. The plate and filter press consists of filter plates and frames arranged to form filter chambers. Under the pressure of the feeding pump, the material is sent into each filter chamber, where the solids and liquids are separated through a filtration medium. The plate frame filter press is widely used in various industries such as chemical, mining, pharmaceuticals, and sewage treatment. The plate and frame filter press has several advantages, including good separation effect, wide range of applications, simple operation, and cost savings.

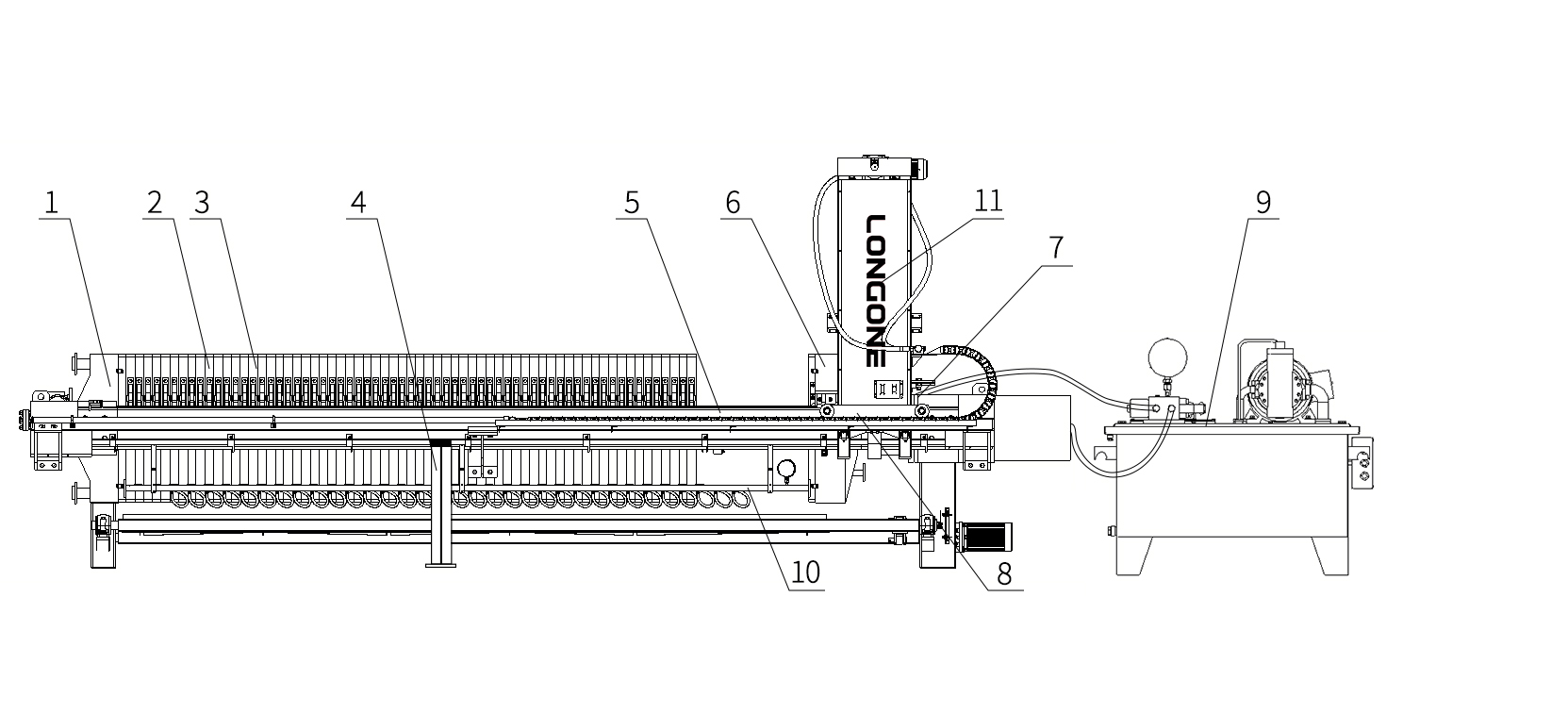

1. Thrust Plate 2. Membrane Plates 3. Chamber Plates 4. Middle Support

5. Main Beam 6. Compression Plate 7. Hydraulic Cylinder 8. Automatic Shifting System

9. Hydraulic Station 10. Squeezing Tube

Key Features of Plate and Frame Filter Press:

Solid Construction: The plate frame filter is made with high-quality stainless steel or carbon steel materials for durability and corrosion resistance.

Flexible Configuration: The plate frame filter is available in various sizes and configurations to accommodate different processing capacities and filtration requirements.

Efficient Filtration: The plate and frame filter press provides effective separation of solids from liquids.

Easy Operation: The plate frame filter press is simple to operate and maintain, with user-friendly controls and automated functionalities available.

Versatile Applications: The plate and filter press is suitable for a wide range of industries including pharmaceuticals, chemicals, food and beverage, mining, and wastewater treatment.

How the Plate and Frame Filter Press Works:

Feeding: The slurry, a mixture of solid particles and liquid, is fed into the plate and filter press chamber.

Filtering: The chamber contains a series of filter plates separated by a filter cloth. As the slurry is pumped into the chamber, the liquid passes through the filter cloth, leaving the solid particles behind.

Dewatering: The liquid, now separated from the solids, exits the chamber through an outlet, while the solids are trapped and form a filter cake.

Pressing: Once the filter plate and frame chamber is filled, the filter plates are pressed together, exerting pressure on the filter cake. This action further reduces the moisture content in the filter cake by expelling the remaining liquid.

Cake Discharge: After dewatering, the plate and filter press is opened, and the dry filter cake is removed manually or mechanically for disposal.

Cleaning: The filter cloths are cleaned or replaced to prepare for the next filtration cycle.

Applications of Plate and Frame Filter Press:

Pharmaceutical Industry: Filtration of antibiotics, enzymes, and pharmaceutical intermediates.

Chemical Industry: Purification of organic acids, resins, and catalyst recovery.

Food and Beverage: Clarification of beverages, oils, and syrups.

Mining: Dewatering of mineral concentrates and tailings.

Wastewater Treatment: Sludge dewatering and effluent polishing.

After-Sales Service and Support:

Backed by a one-year warranty and comprehensive technical support to ensure optimal performance throughout the product lifecycle. We offer lifelong maintenance services, free software updates, and upgrades, along with long-term preferential supply of spare parts and accessories.

Company Profile:

Founded in 2007, Longone Equipment Inc. is a leading provider of filtration system solutions. We specialize in high-quality filter presses and accessories, serving industries such as pharmaceuticals, chemicals, food and beverage, mining, and wastewater treatment.

Click here to enter our VR factory.

Service Philosophy: Customer First, Rapid Response

At Longone, we prioritize customer needs and quick responses:

Professional Technical Support: Our experienced engineers offer fast and expert assistance with installation, maintenance, and troubleshooting.

Customized Solutions: We provide tailored filtration solutions to meet specific customer requirements.

Rapid After-Sales Service: Our 24/7 support team ensures minimal downtime with swift issue resolution and on-site service.

Ample Spare Parts Supply: We maintain a robust inventory for quick fulfillment of spare parts needs.

Ongoing Training and Consultation: Regular training and follow-ups help customers optimize equipment use and maintenance.

Committed to innovation and excellence, Longone continues to enhance product quality and service standards, aiming to lead the global filtration equipment industry. For inquiries and collaborations, we look forward to partnering with you!