- Home

- >

- Products

- >

- Filter Plate

- >

- Membrane Plate

- >

Introduction to Membrane Plates:

Membrane plates are an integral component of filter presses, providing advanced solutions for solid-liquid separation across various industries, including chemical, mining, and water treatment. These membrane filter plates feature a sophisticated design with expandable membranes, resulting in higher dewatering efficiency. The ability to compress the filter cake after the initial filtration phase sets membrane plates apart from traditional chamber plates, offering significant operational advantages.

Features of Membrane Plates:

High Dewatering Efficiency: The heart of the membrane filter plates is the expandable membrane, typically made from rubber or polypropylene. During the filtration process, these membranes can be inflated to exert additional pressure on the filter cake. This secondary compression step significantly increases the dryness and solid content of the filter cake.

Excellent Corrosion Resistance: Constructed from high-strength polypropylene or other corrosion-resistant materials, membrane plates can withstand harsh chemical environments.

Sturdy Construction: Membrane plates are designed to endure high-pressure conditions. Their construction ensures that the diaphragm filter plates remain stable, even during intensive filtration cycles.

Easy Operation and Maintenance: The user-friendly design of membrane plates simplifies their operation and maintenance. The membrane filter press plates are easy to install, remove, and clean, which reduces maintenance time and costs.

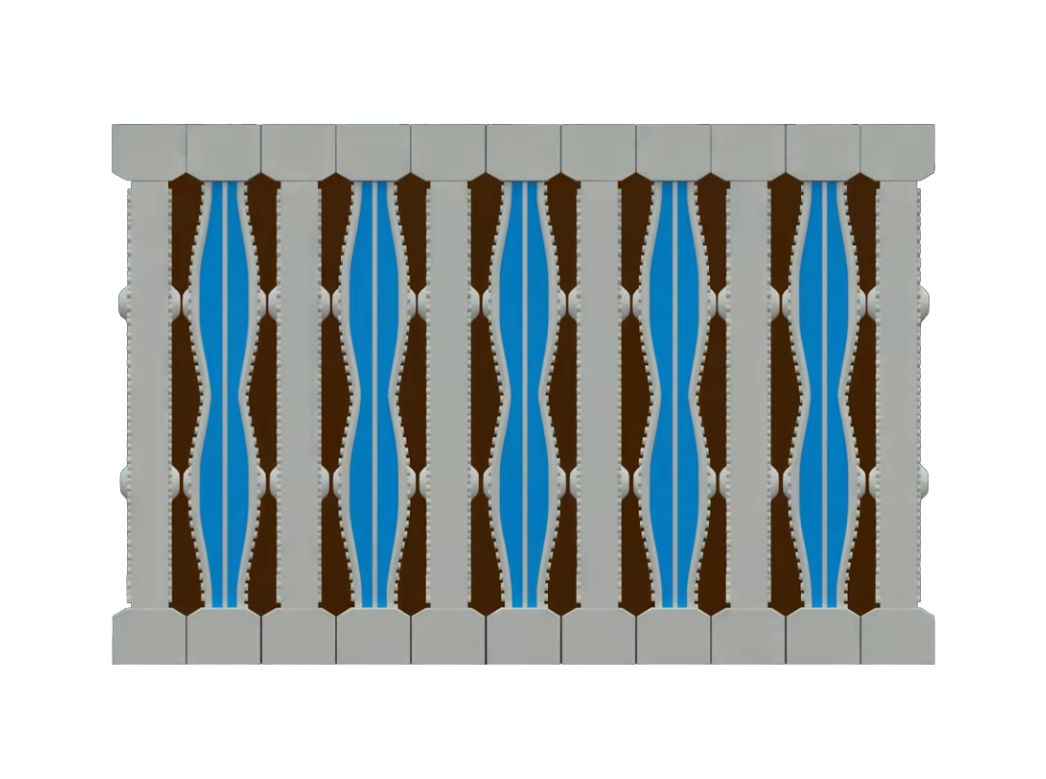

Working Principle of Membrane Plates:

The operation of membrane plates involves forming a sealed filtration chamber between the membrane filter plates and filter cloth. When slurry is pumped into this chamber, the filtrate passes through the filter cloth, while solid particles are retained, forming a filter cake. After the initial filtration phase, the membrane inflates using air or liquid, exerting additional pressure on the filter cake. This secondary compression step removes more moisture from the filter cake, achieving a higher degree of dewatering.

Our Service for Membrane Plates:

Longone provides an operation manual for the filter press and filtration elements, detailing specifications and warnings.

Longone can optimize filtration technical data and develop operation guidelines tailored to customer needs.

Longone offers customized filtration flow charts based on different materials and requirements.

Longone provides free filtration testing services.

Identify the most suitable technical data (time, pressure, cake thickness, washing water capacity).

Evaluate solid content, processing capacity, permeability, and cake resistance.

Assess the feasibility of cake washing.

Conduct flocculation testing for suspensions.

Select appropriate filtration cloth.

Longone offers complimentary training, covering:

Safety precautions; Installation and commissioning; Operation of filtration plates; Methods for handling abnormal conditions; Troubleshooting.

Membrane Plates Work Shop:

5-Axis Processing Line For Filter Plate:

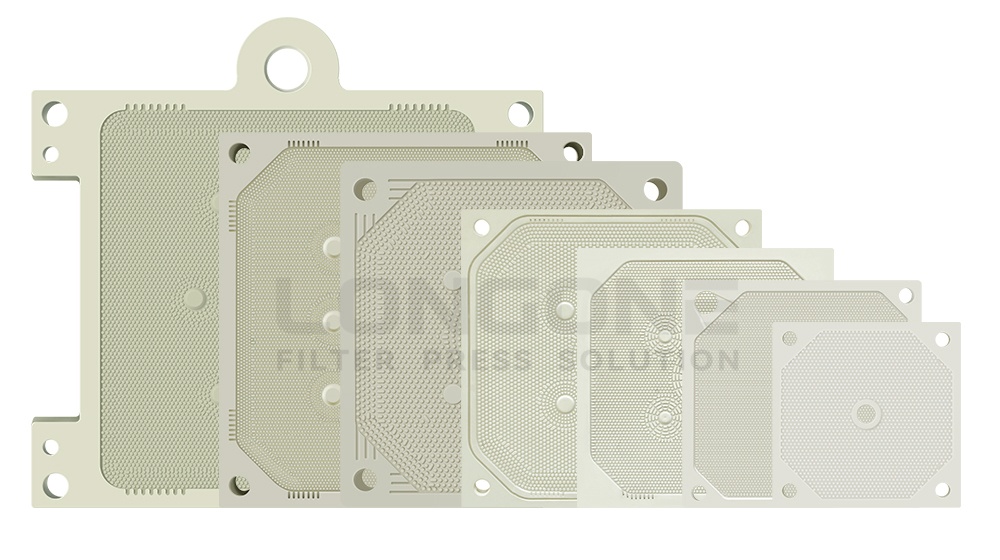

Longone's Membrane Plates:

Classified by SIZES

1000mm membrane filter plate

1250mm membrane filter plate

1500mm membrane filter plate

2000mm membrane filter plate

Membrane filter rubber plate

By integrating membrane filter press plates into the filtration systems, businesses can achieve higher productivity, lower operational costs, and ensure the production of high-quality products. For inquiries about purchasing diaphragm filter plates and other filter press components, please contact us.