- Home

- >

- Products

- >

- Filter Press

- >

- Sludge Filter Press

- >

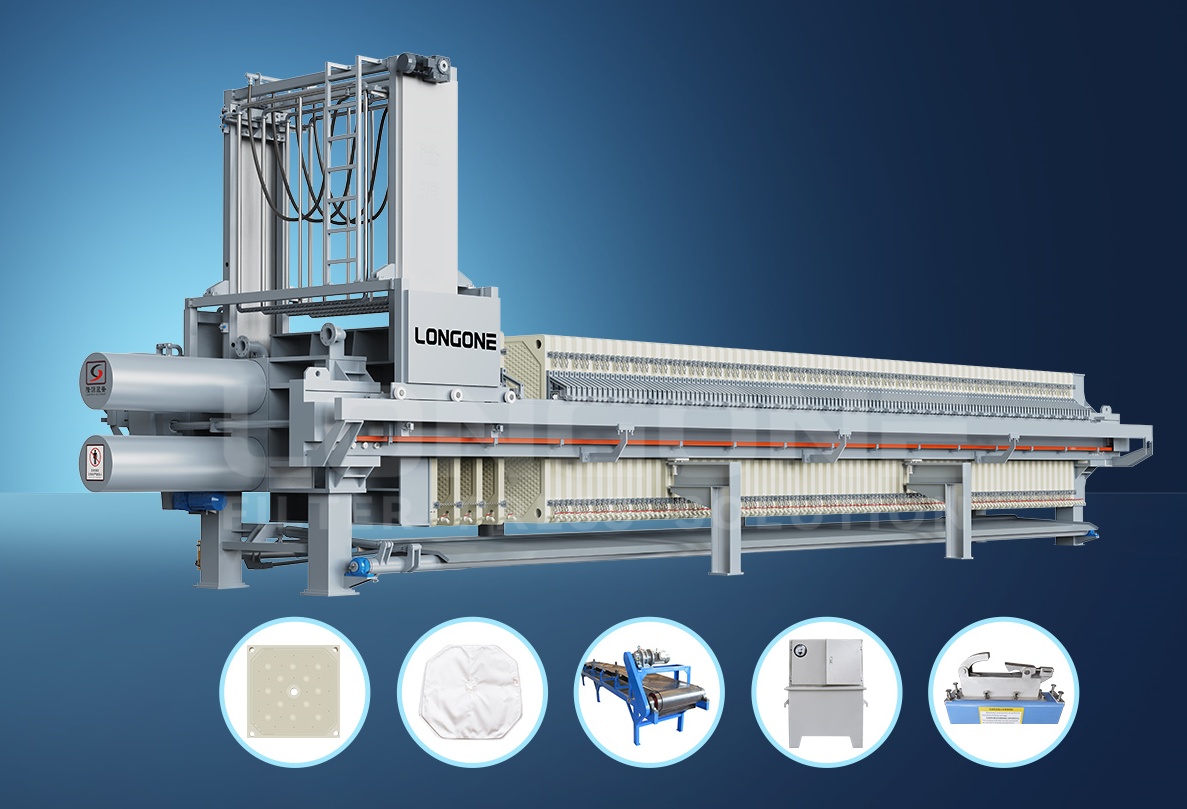

Introduction to Sludge Filter Press:

Nowadays, the efficient management of wastewater has become increasingly paramount. Global industries are in a constant pursuit of innovative methods to purify wastewater, ensuring it adheres to environmental benchmarks. The sludge filter press stands as a prominent instrument in this domain.

The filter press for sludge dewatering serves as specialized machinery across various industries for the separation of solids from liquids. Within the realm of wastewater treatment, The function of the sludge press is to eliminate impurities from water and aid in the management of residual sludge. The operation begins with pumping the slurry into the sludge press machine, followed by the exertion of substantial pressure to compel the liquid through a filtering medium, yielding a filter cake.

Applications of Sludge Dewatering Filter Press:

Our sludge filter presses are tailored to address an array of sludge varieties, spanning municipal, industrial, and biological sources.

Municipal Wastewater Treatment:

In municipal wastewater treatment plants, the sludge filter presses are utilized to dewater the sludge which contains a high concentration of organic matter and solids. This not only reduces the volume of waste but also minimizes transportation and disposal costs.

Industrial Wastewater Treatment:

Industries such as chemical, food processing, paper manufacturing, and mining generate sludge. Sludge filter presses are employed to dewater this sludge, which can vary significantly in composition and characteristics. The sludge press ensures that the sludge is treated to meet environmental regulations, reducing the environmental impact and turning a waste product into a more manageable material that can be safely disposed of or, in some cases, recycled.

Agricultural Wastewater Treatment:

Agriculture can produce sludge from sources such as manure and other organic waste materials. Sludge filter presses are used to dewater these materials, creating a more stable and hygienic end product. The dewatered sludge can then be used as a soil conditioner or in the production of biogas through anaerobic digestion, contributing to a circular economy in agricultural waste management.

Filter Presses for Sludge Dewatering Advantages:

The key advantages of sludge filter include:

Exceptional Efficiency: With the capacity to extract nearly all solid particles from wastewater, the filter press for sludge dewatering alleviates the burden on downstream purification processes.

Economical: Producing a compact sludge cake, the sludge press machine curtails waste volume, thus economizing on transportation and disposal expenses.

Regulatory Adherence: The sludge filter empower industries to navigate environmental regulations by guaranteeing effluent is devoid of harmful contaminants.

Operational Prowess: Characterized by high operational efficiency, the sludge press often surpasses alternative dewatering techniques.

Sludge Types Treated by Sludge Filter Presses:

The sludge filter is effective for nearly all types of sludge:

Hydrophilic Organic Sludge: Often requires inorganic conditioning to facilitate satisfactory filter cake release due to minimal adherence to the filter cloth.

Hydrophilic Inorganic Sludge: Generally only needs the addition of lime.

Hydrophobic Inorganic Sludge: Ideal for the sludge dewatering filter press as it is very dense and can be dewatered without preliminary conditioning.

Oily Sludge: The sludge dewatering filter press is suitable for treating sludge containing light oils. However, the grease may occasionally hinder smooth operation, necessitating frequent degreasing of the filter cloths.

For industries seeking to refine their wastewater management protocols, the filter press for sludge dewatering presents a well-rounded solution for efficient, economical, and eco-friendly sludge management. Engage with us to discover how the sludge press machine can enhance your operational sustainability.

Enterprise Profile:

Since 2007, Longone Corporation has specialized in advanced filtration systems, offering a range of automatic sludge filter presses suitable for various industries. Our product lineup includes PP Recessed Plate, PP Membrane Plate, CGR Plate, and essential accessories.

Longone is committed to quality, holding ISO9001, CE certifications and other certifications. We are dedicated to innovation, constantly enhancing our manufacturing to surpass industry standards, solidifying our position as a trusted global filtration solutions provider.