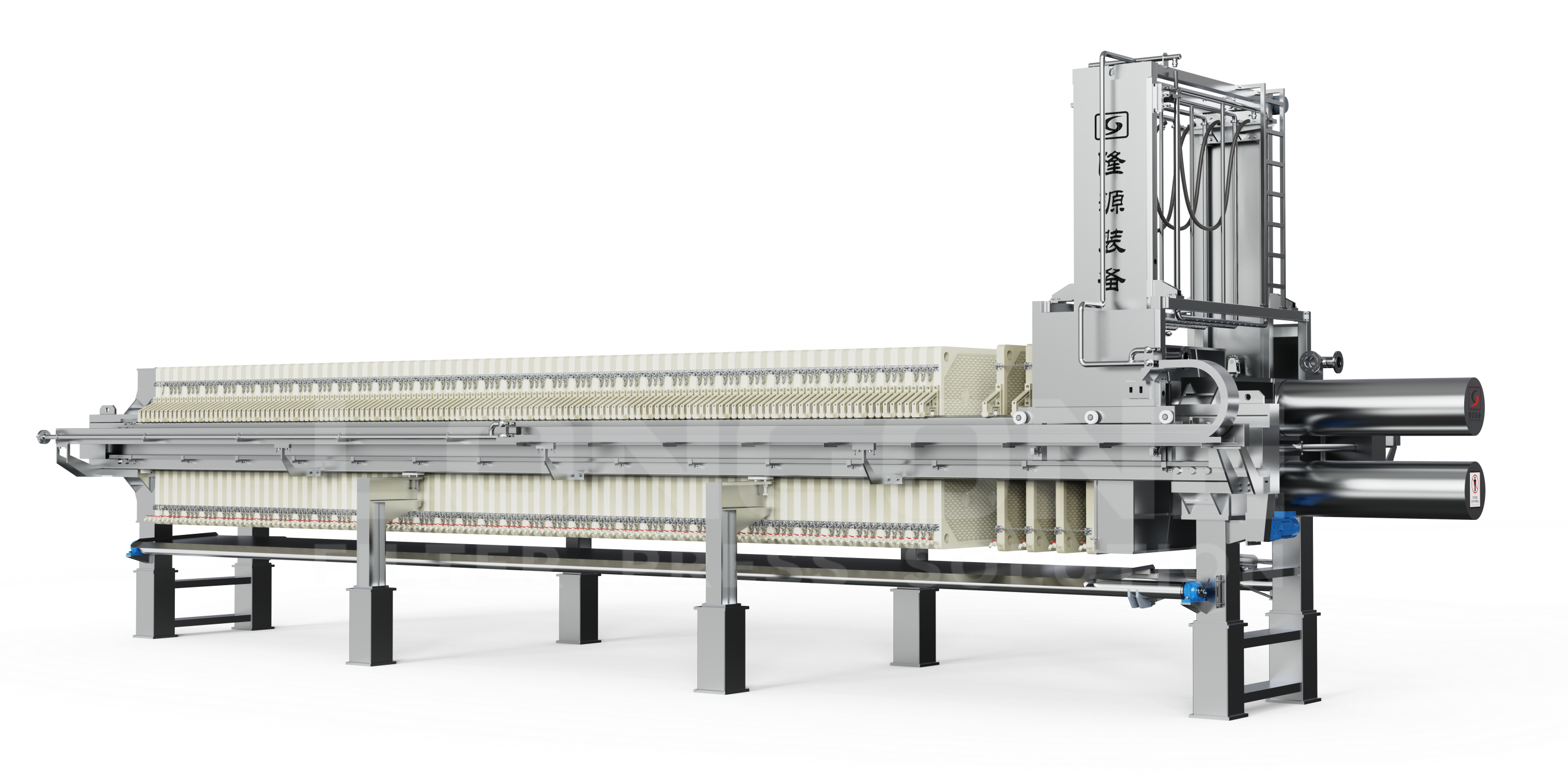

Introduction to Stainless Steel Filter Press:

The stainless steel filter press, a type of plate and frame filter press is an equipment designed for the effective solid-liquid separation. The ss filter press's core lies in the precision-crafted stainless steel plates and frames, which form a series of chambers where filtration takes place. This robust construction ensures that the industrial filter press can withstand the toughest conditions, making it an ideal choice for industries where reliability and longevity are paramount.

Basic Parameters of Stainless Steel Filter Press:

| Material | High-grade stainless steel (304, 316L) |

| Plate Size | 250mm x 250mm to 2000mm x 2000mm |

| Filtration Area | 0.16m² to 1600m² |

| Feeding Type | Top feeding, center feeding, corner feeding |

| Filter Plate Type | Membrane type, rubber membrane type, plate and frame type, chamber type, welded PP membrane type |

| Filter Pressure | 0.6 MPa to 6.0 MPa |

| Filtration Temperature | -40℃ to 120℃ |

| Hydraulic System | Manual, semi-automatic, or fully automatic options |

Key Components of Stainless Steel Filter Press

Filter Plates & Frames: Made from high-quality stainless steel (304, 316L), they are designed to withstand high pressures and corrosive substances.

Filter Cloth: Made from high-quality materials, filter cloths are designed to be durable and easy to clean. They are available in different pore sizes to accommodate various filtration needs.

Hydraulic System: Powers the opening and closing of the plate frame filter press, ensuring a tight seal during filtration and facilitating quick and efficient cake discharge.

Control Panel: For automated ss filter presses, the panel allows for programming and monitoring of the filtration process, ensuring consistent performance and reducing the manual intervention.

Stainless Steel Filter Press Highlights:

Superior Durability: The stainless steel construction guarantees long-term reliability, even in harsh environments or with aggressive chemicals.

High Efficiency: Advanced filter plates and frames ensure effective separation of solids from liquids, producing cleaner filtrate and drier cake.

Versatility: Available in various sizes and configurations, the SS Filter Press caters to diverse industrial needs, from small-scale operations to large-scale production lines.

Easy Maintenance: Smooth stainless steel surfaces simplify access to internal components for routine maintenance and cleaning.

Automated Operation: Automation features streamline the filtration process, reducing human error and maximizing productivity.

Customization: The stainless steel filter press can be customized. Options include different plate sizes, filtration capacities, automation levels and so on.

Applications of the SS Filter Press:

Mining Industry: The ss filter press excels at dewatering tailings and concentrates, reducing transportation costs and environmental impact. This kind of industrial filter press is able to handle abrasive slurries and withstand harsh conditions.

Food & Beverage Processing: The stainless steel construction of the industrial filter press ensures compliance with stringent food safety regulations, while its high filtration efficiency preserves the quality and flavor of products. From fruit juices to dairy products, the ss filter press delivers consistent results.

Pharmaceutical Manufacturing: Pharmaceutical manufacturers rely on the ss filter press for the precise separation of active ingredients from solvents, ensuring the purity and potency of their products. SS filter press's corrosion resistance and ease of cleaning make it an ideal choice for sterile filtration processes.

Wastewater Treatment: The ss filter press plays a crucial role in sludge dewatering, reducing the volume of waste for disposal and recovering valuable water for reuse.

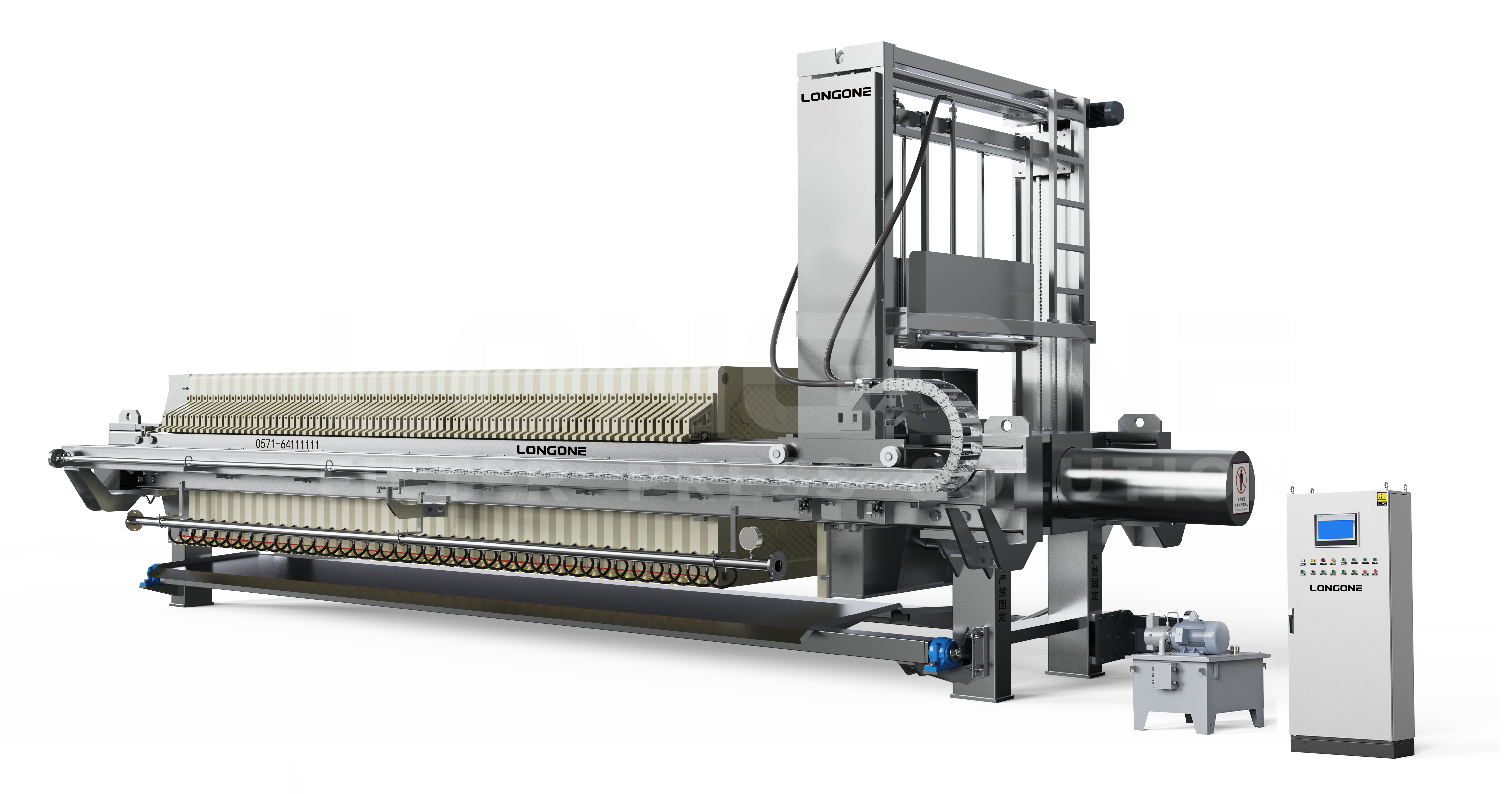

The stainless steel filter press is an indispensable tool for industries requiring high-quality filtration. Its durability, efficiency, and versatility make it a preferred choice. By integrating a stainless steel filter press into your operations, you can achieve unparalleled filtration performance. Longone also has other types of plate and filter presses for you to choose from.

Enterprise Profile:

Longone is a leading manufacturer dedicated to producing high-quality plate and frame filter presses, filter plates, and a range of complementary equipment and accessories. Our products are widely used across various industries including chemical, pharmaceutical, food, and environmental protection, earning a reputation for their exceptional performance and reliability.

At Longone, we are committed to providing customized filtration solutions through innovative technology and superior service, helping our clients to enhance production efficiency and product quality. Choose Longone for professionalism and trust. Click here to enter our VR factory.