If you're prioritizing efficiency during the squeezing process of the filter press, a Membrane plate filter press could be an ideal choice.

Typically, a standard chamber filter press requires about 4 hours to complete the filling phase, though this can vary based on the properties of differrnt slurry. Conversely, a membrane squeeze filter press can potentially cut the cycle time by about half, on average. In certain scenarios, it might even reduce it by up to three-quarters, depending on the specific application.

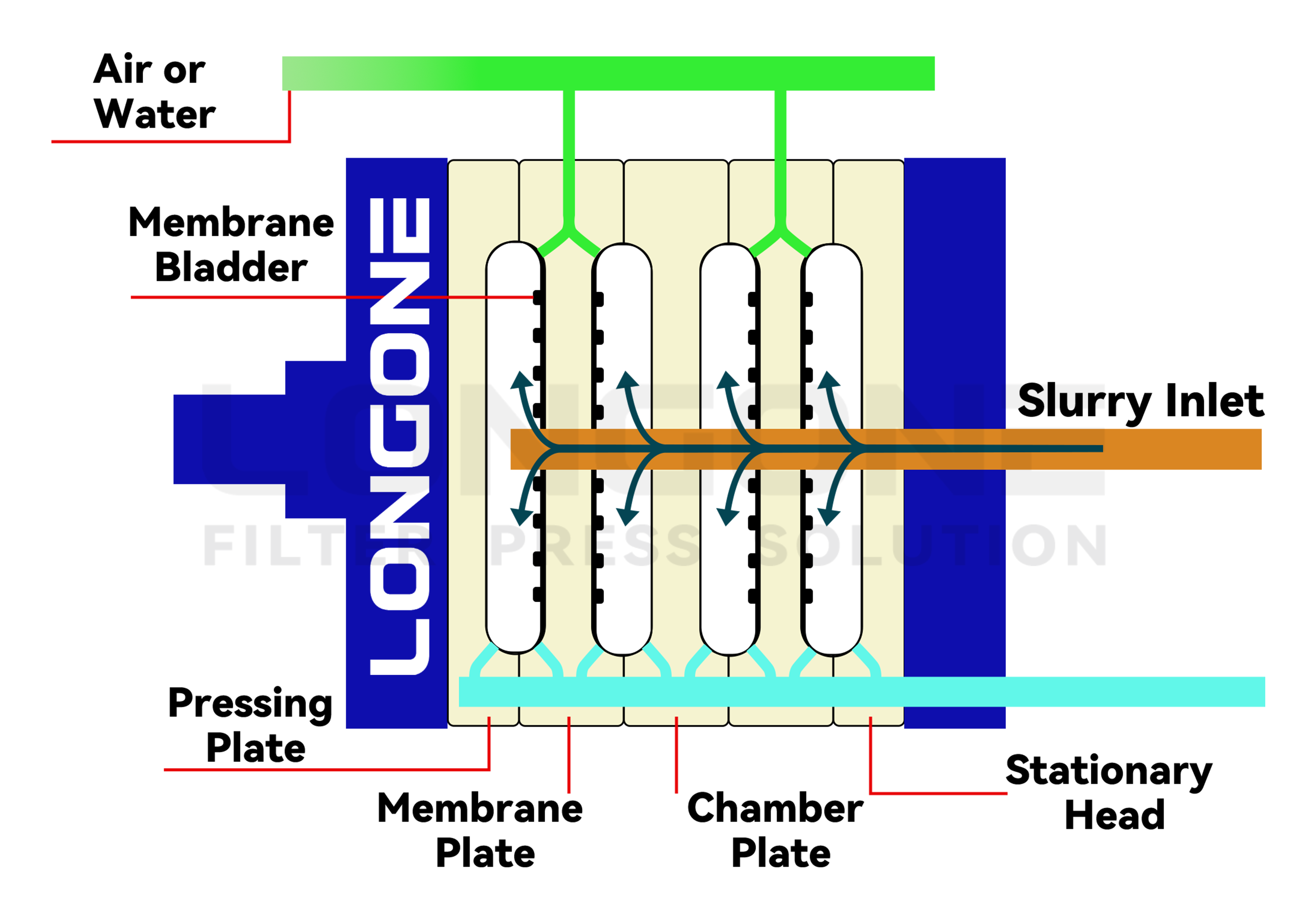

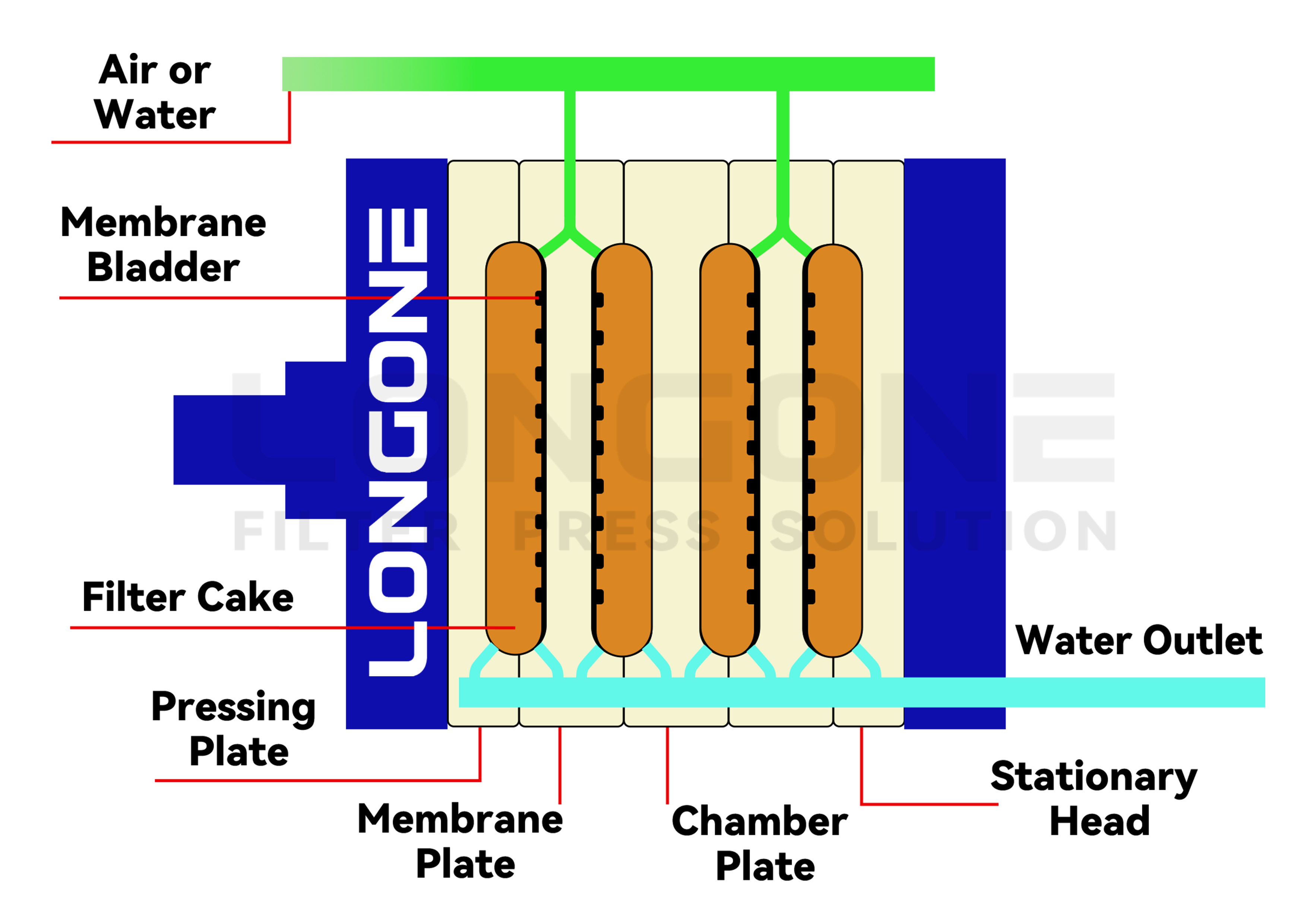

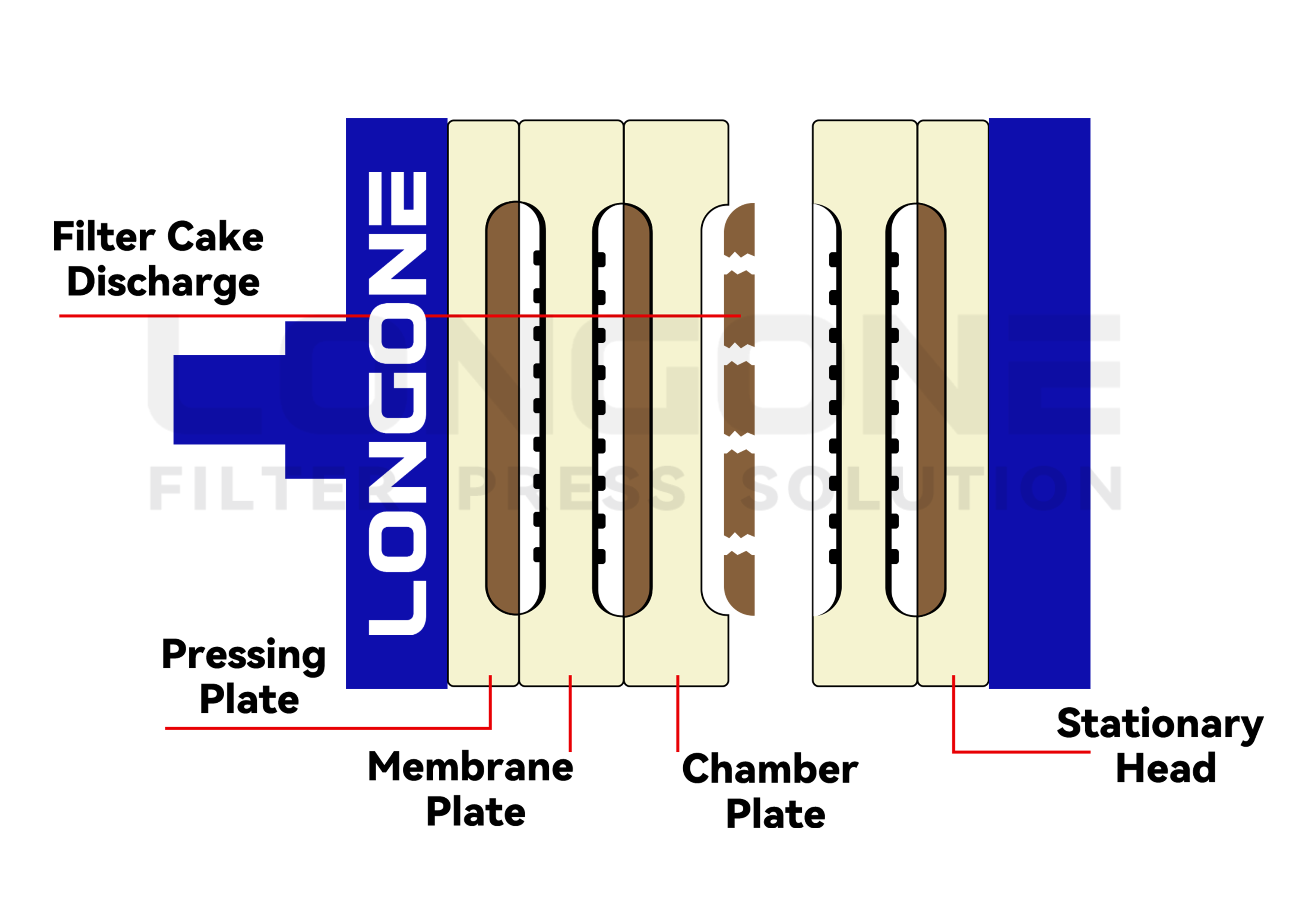

The membrane filter press stands out for its multi-functional capabilities. The membrane squeeze filter press operates by initially filling the chambers with slurry. Once the chamber is filled, the membrane plates apply additional pressure by inflating, squeezing the slurry, and expelling more filtrate. This process results in a much drier filter cake compared to chamber filter presses.

The membrane automatic filter press features high-strength filter plates that withstand high pressures, ensuring durability and reliability. The diaphragm filter press, with its flexible membrane, adapts to varying pressures up to 60 bar and provides optimal filtration efficiency.

Membrane squeeze filter press Material | High-grade stainless steel (304, 316L), carbon steel Q345 |

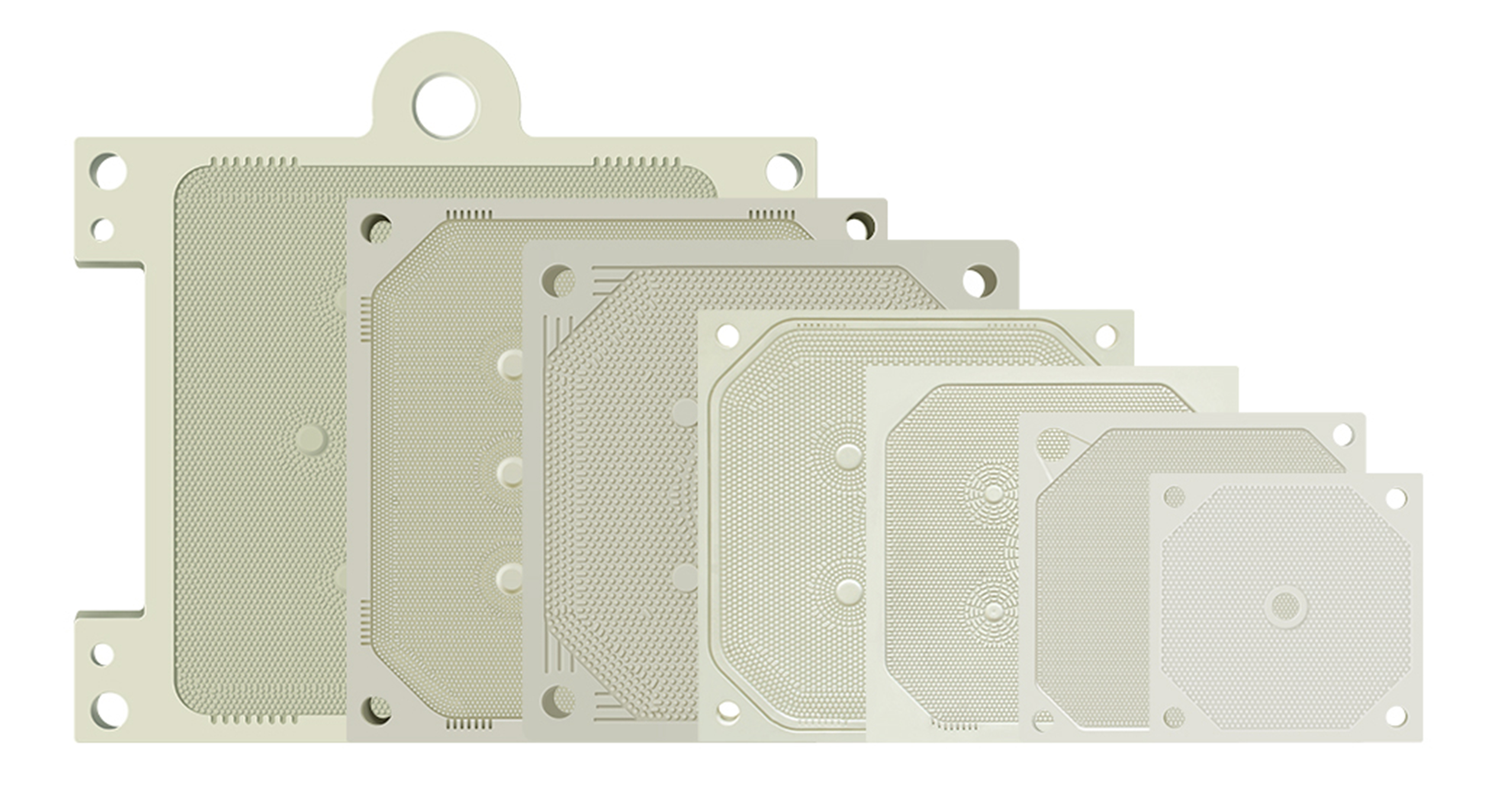

Membrane squeeze filter press Filter Plates Size | 250mm×250mm to 2000mm×2500mm |

Membrane squeeze filter press Filtration Area | 0.16m² to 1600m² |

Membrane automatic filter press Feeding Type | Top feeding, center feeding, corner feeding |

Membrane automatic filter press Filter Plates Type | Membrane type, rubber membrane type |

Membrane plate filter press Filter Pressure | 0.6 MPa to 6.0 MPa |

Membrane plate filter press Filtration Temperature | -40℃ to 120℃ |

Membrane plate filter press Hydraulic System | Manual, semi-automatic, or fully automatic options |

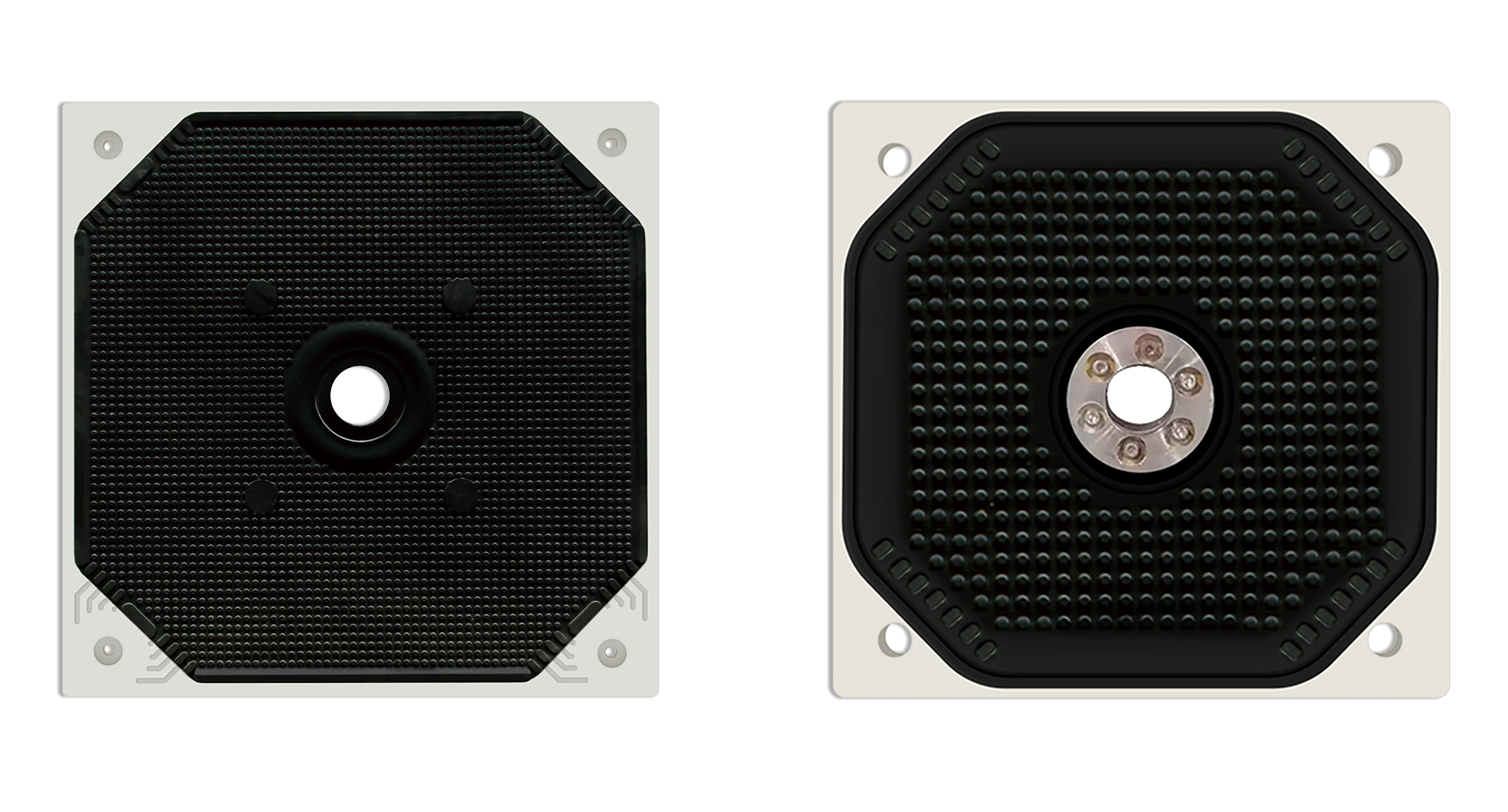

Filter Plate Structure: The filter plates in a membrane squeeze filter press are composed of two layers: a rigid support layer and a flexible membrane layer. The membrane, typically made of rubber or TPE elastomers, is designed to be stretchable and resistant to chemical corrosion.

Stage 1-Filling Stage:The slurry is pumped into the membrane automatic filter press's chamber between the filter plates. Solid particles accumulate on the filter cloth, forming a filter cake, while the filtrate passes through the filter cloth and is discharged.

Stage 2-Filtration Stage: Once the filter cake reaches a predetermined thickness, the slurry pushed by the feeding pump will force the liquid out from the chambers. The filter plates and filter cloths will capture the solid.

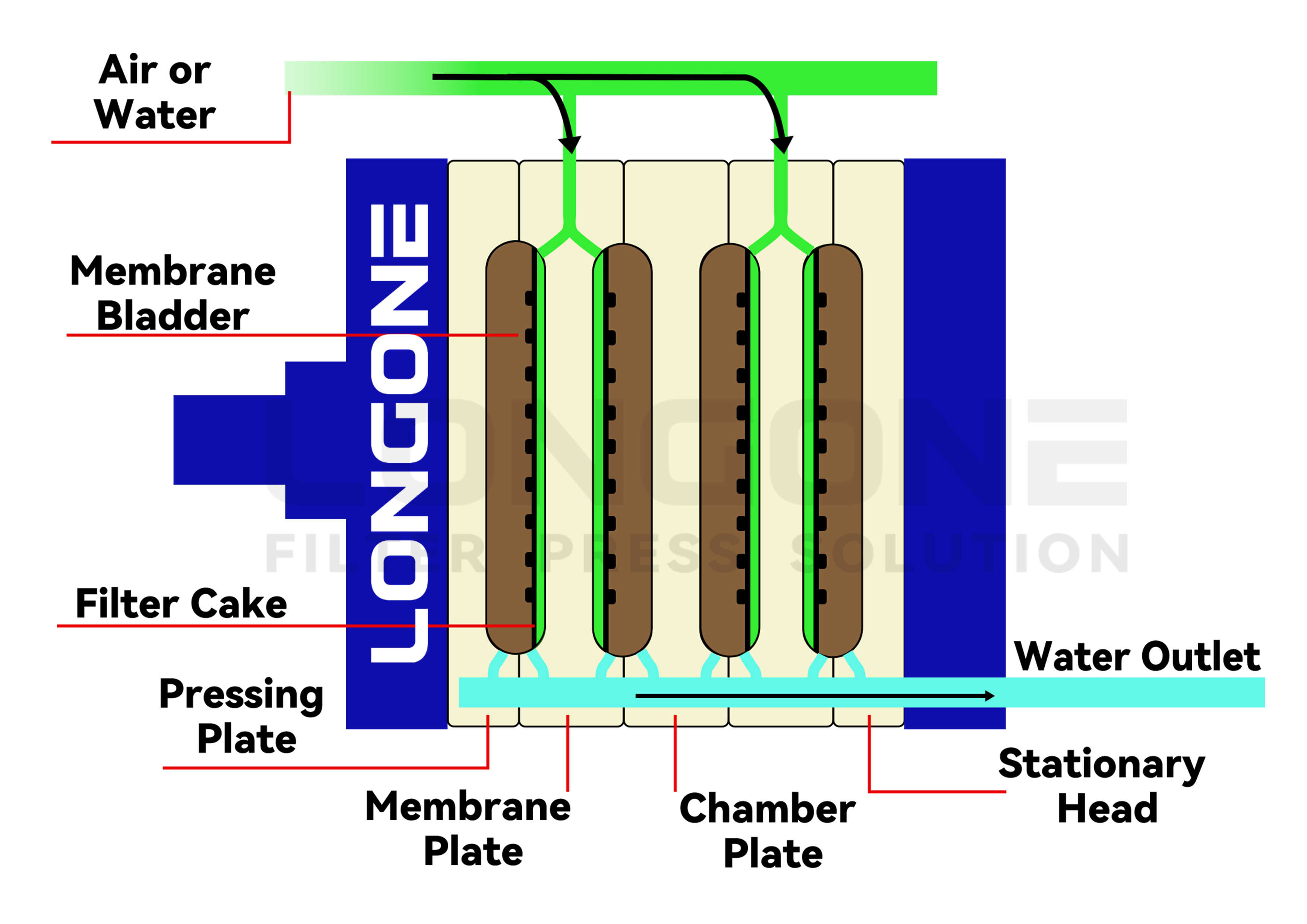

Stage 3-Compression Stage: Once the feeding cycle is completed, the feeding system will be closed and the membrane squeezing system will start. Compressed air or liquid (such as water) is introduced into the space between the membrane and the support layer. The membrane expands and exerts uniform pressure on the filter cake. This additional pressure expels more liquid from the filter cake, reducing its moisture content.

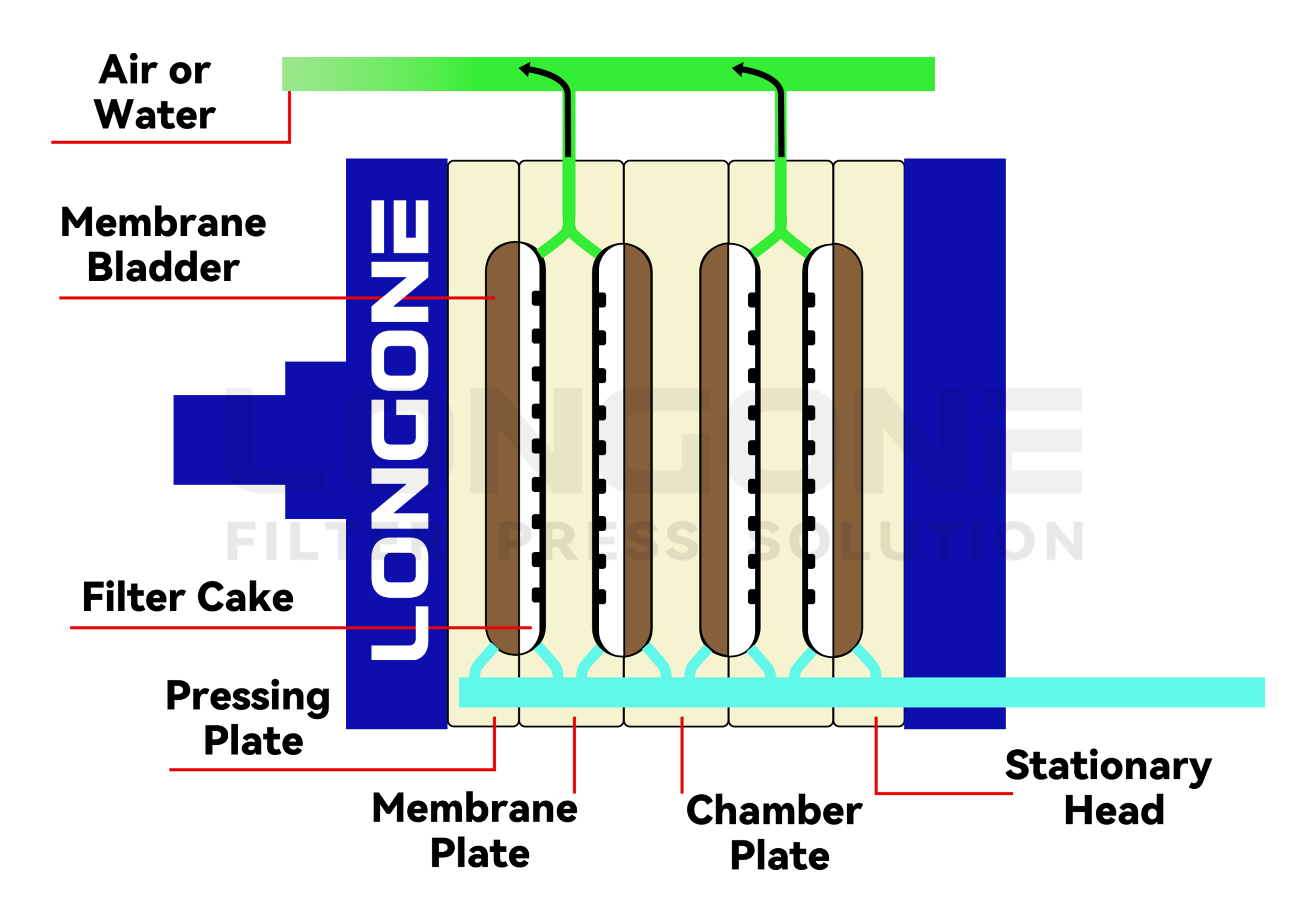

Stage 4-Draining Stage: Once the compression stage is completed. The air or water will drain from the membrane plate filter press.

Stage 5-Cake Discharge Stage: Each high pressure filter press chamber is opened up and the filter cake is discharged.

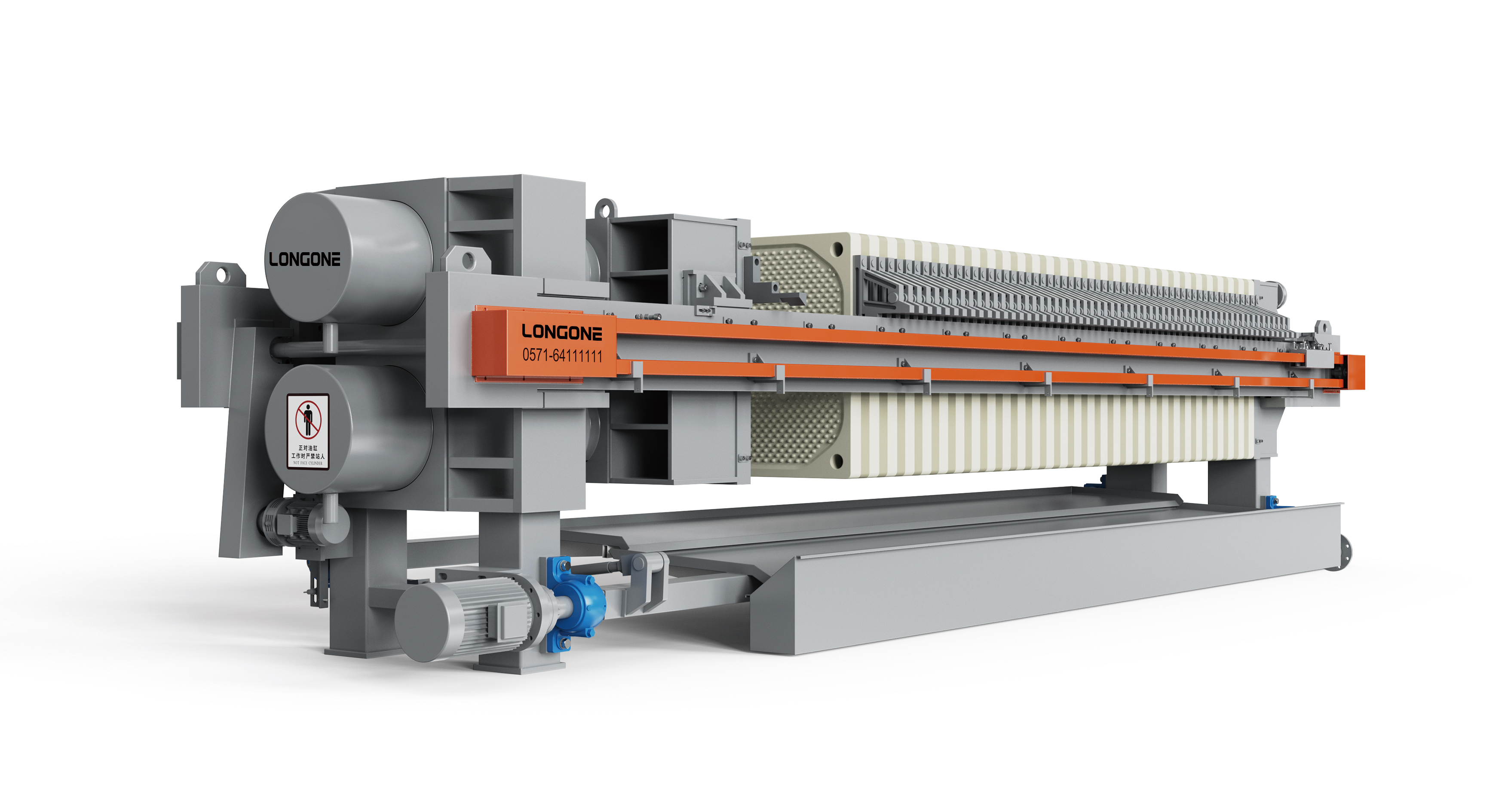

Longone Diaphragm Filter Press with Double Hydraulic Cylinder

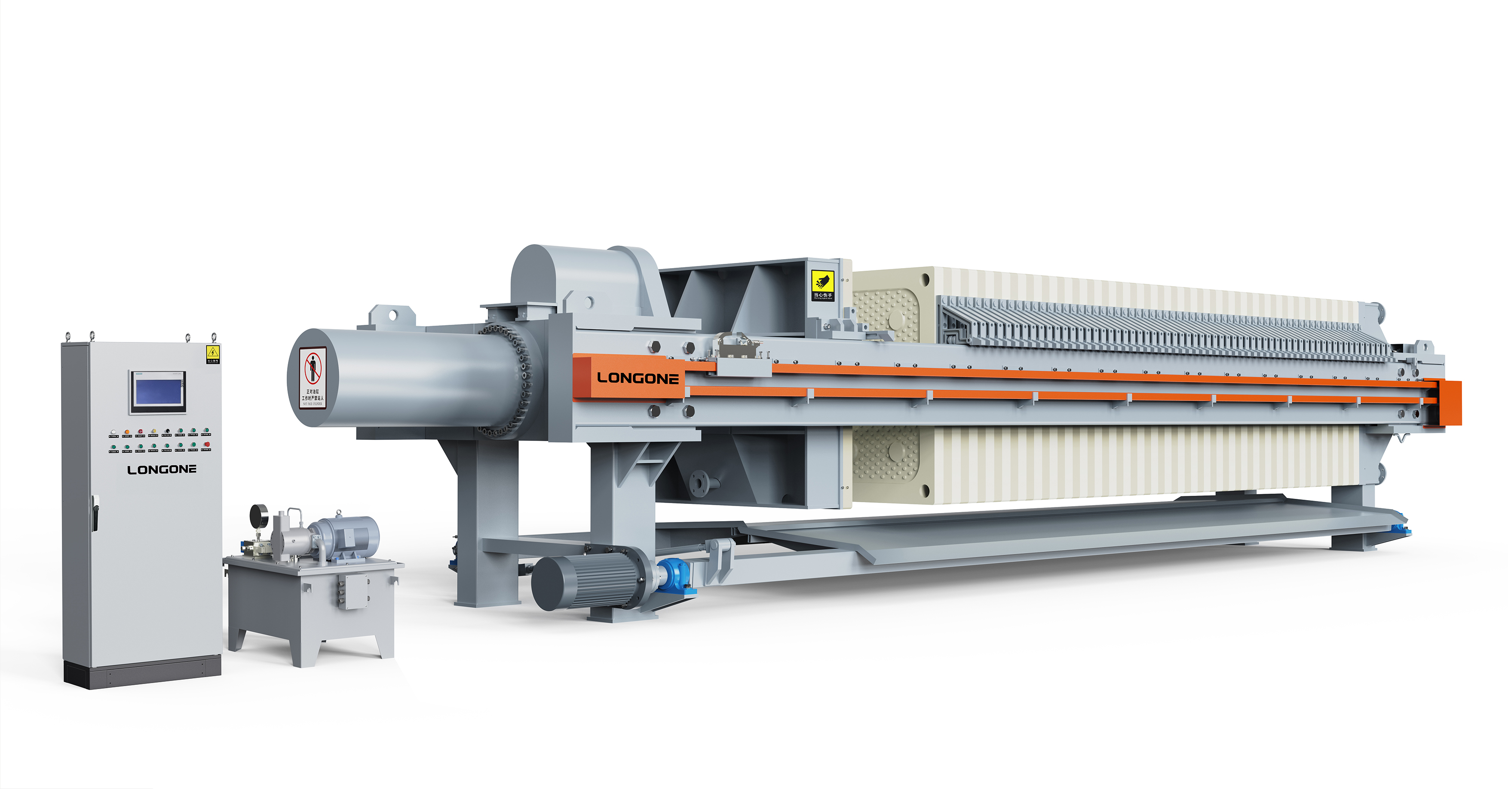

Longone Membrane Filter Press with Hydraulic Cylinder Locking Block

Polypropylene Membrane Plates

Rubber Membrane Plates

Improved Filtration Efficiency: Membrane squeezing significantly enhances the solid content of the filter cake, reducing post-processing costs.

Reduced Processing Time: The squeezing process shortens the overall filtration cycle as it quickly expels residual filtrate from the filter cake.

Enhanced Filter Cake Quality: The uniform pressure during membrane squeezing improves the density and strength of the filter cake, making it easier to handle and transport.

High Flexibility: Membrane plate filter presses are suitable for various industrial applications, including chemical, pharmaceutical, and wastewater treatment.

Diaphragm filter press in Chemicals

Diaphragm filter press in Mining & Minerals

Diaphragm filter press in Pharmaceuticals

Diaphragm filter press in Environment and Wastewater

Diaphragm filter press in Food

Diaphragm filter press in New Energy

Whether you're looking to optimize your material treatment process, enhance product recovery rates, or streamline your workflow, our membrane plate filter presses is tailored to meet your unique needs. With a commitment to innovation, quality, and customer satisfaction, we invite you to explore the possibilities of our advanced filtration solutions.