Introduction to Discharge Filter Press:

The discharge filter press is an essential equipment used in various industries for the separation of solids from liquids. There are four types of discharge filter presses: manual discharge, handle knock discharge, cranked knock discharge, and gantry knock discharge.

Manual Discharge Filter Press:

The manual discharge filter press is the simplest type of the dewatering filter press. It relies on labor to manually remove the filter cake from the filter plates after the filtration process is complete. This type is often used in smaller operations or in situations where automation is not feasible.

Advantages:

Cost-Effective: Since it does not require complex machinery or automation, the manual discharge filter press is relatively inexpensive.

Simplicity: The manual discharge filter press is easy to operate and maintain.

Flexibility: This kind of discharge filter press can be used in various applications without extensive modifications.

Applications:

Water Treatment: Often used in water filter press systems for small-scale water purification processes.

Small Businesses: Ideal for operations with lower filtration volumes and where a small filter press is sufficient.

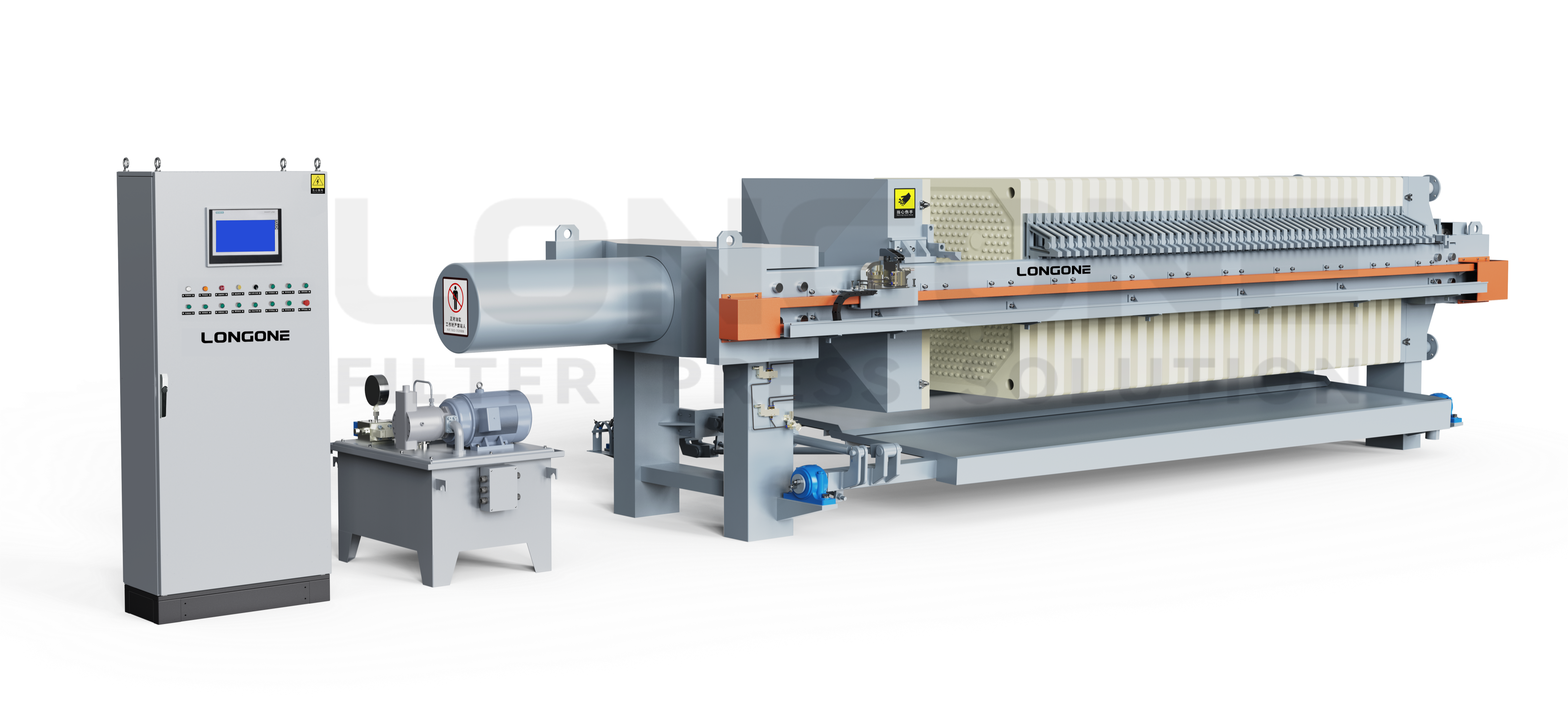

Handle Knock Discharge Filter Press:

The handle knock discharge filter press features a handle mechanism that facilitates the removal of the filter cake. Operators use the handle to knock the filter plates, dislodging the filter cake more efficiently than manual methods.

Advantages:

Improved Efficiency: Reduces the time and effort required to remove the filter cake compared to manual discharge.

User-Friendly: The handle mechanism is easy to use, requiring minimal training.

Versatility: Suitable for various applications, including those requiring a horizontal filter press configuration.

Applications:

Industrial Filtration: Used in industries where moderate volumes of filtration are needed.

STP (Sewage Treatment Plants): Employed in filter press in STP applications to enhance the efficiency of sludge dewatering.

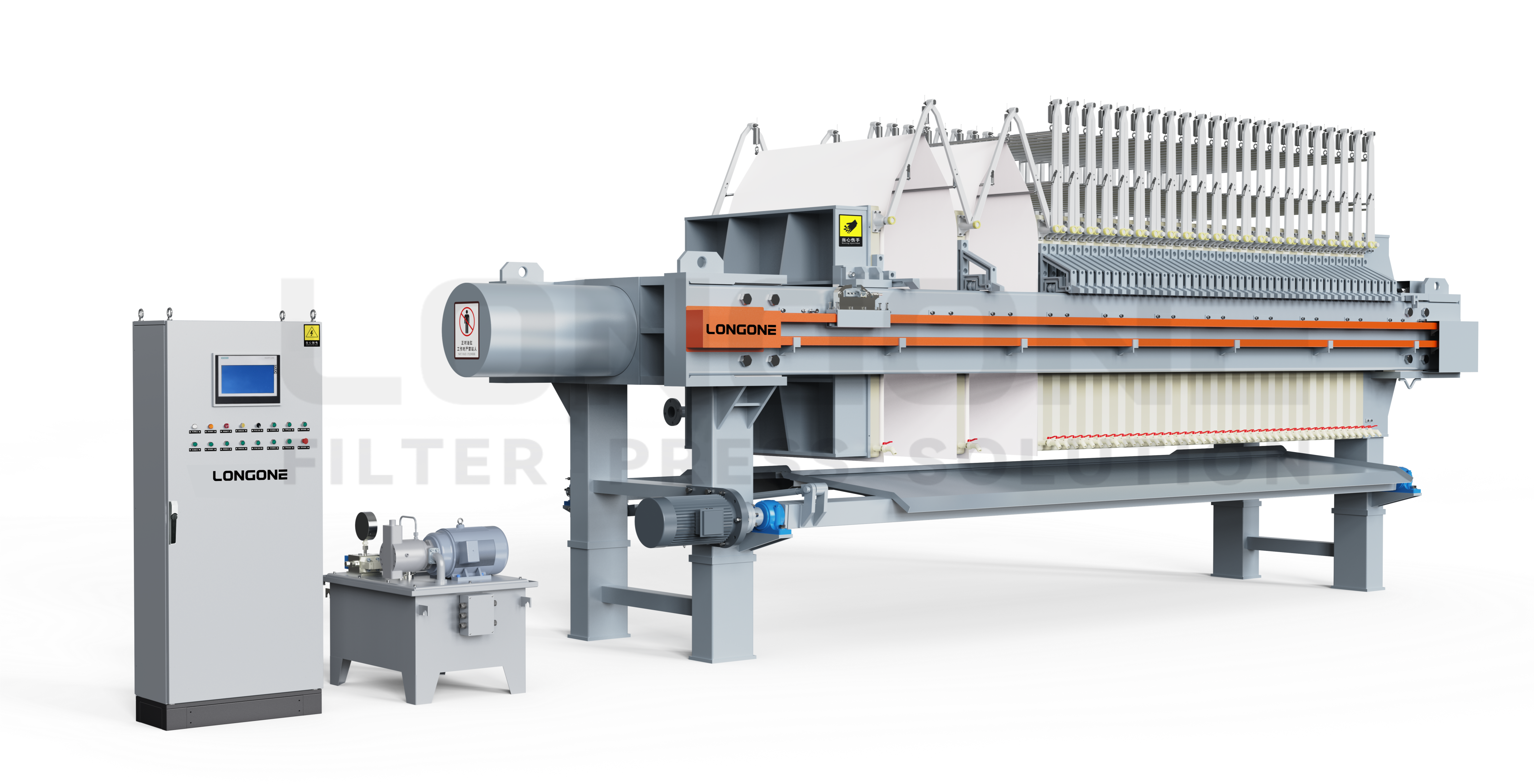

Cranked Knock Discharge Filter Press:

The cranked knock discharge filter press utilizes a crank mechanism to knock and dislodge the filter cake from the filter plates. This type offers a higher degree of automation compared to the handle knock discharge.

Advantages:

Enhanced Automation: The crank mechanism provides a more automated approach, reducing manual labor.

High Efficiency: Ensures thorough removal of the filter cake, improving overall filtration efficiency.

Robust Design: Designed to handle more demanding filtration tasks.

Applications:

Chemical Processing: Commonly used in chemical plants where efficient filtration is critical.

Large-Scale Operations: Suitable for larger filtration systems that require a horizontal filter press setup.

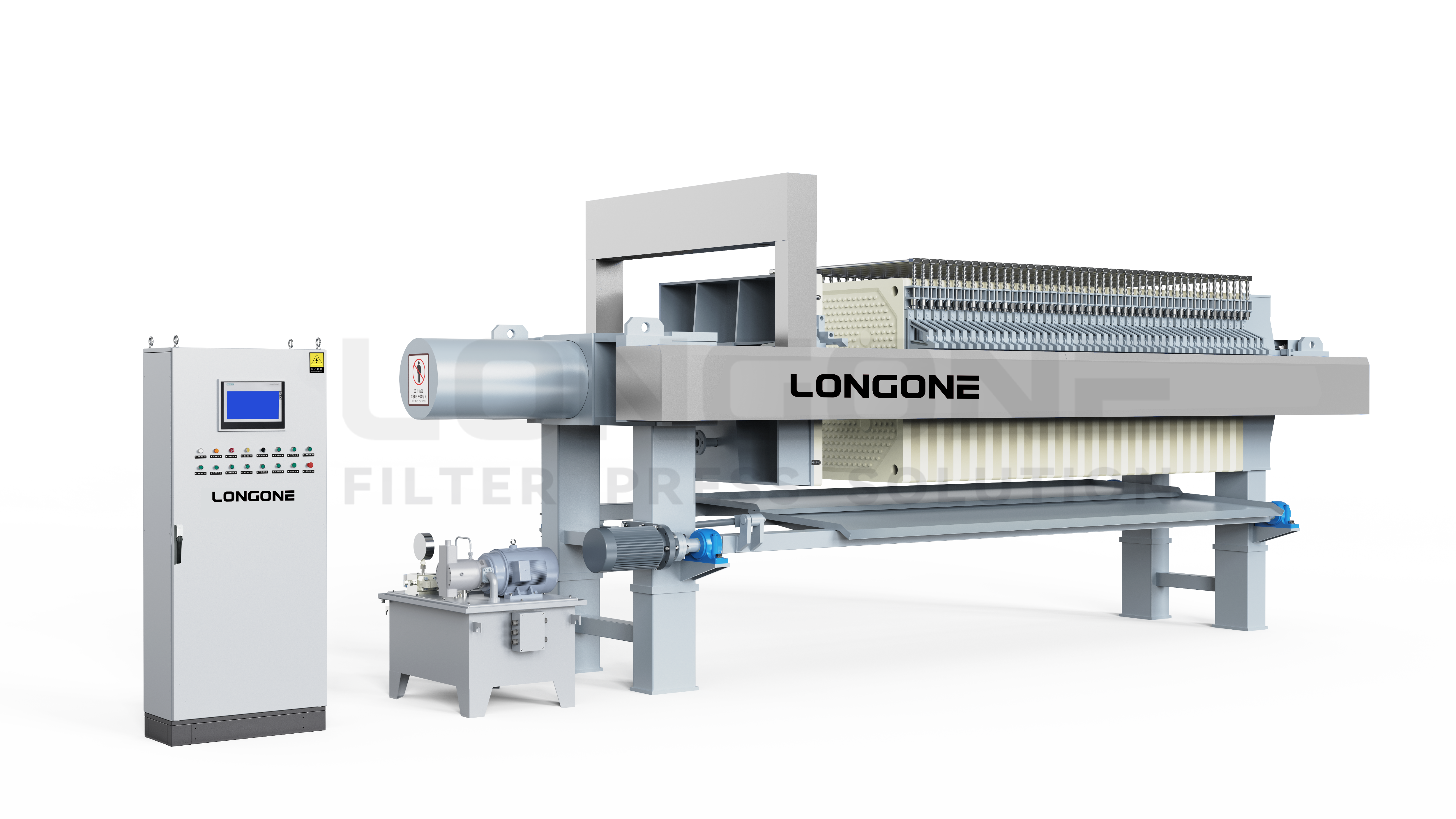

Gantry Knock Discharge Filter Press:

The gantry knock discharge filter press represents the most advanced type of discharge mechanism. It employs a gantry system that automatically knocks and discharges the filter cake from the plates, offering the highest level of automation.

Advantages:

Maximum Efficiency: Fully automated system significantly reduces the need for manual intervention.

High Throughput: Capable of handling large volumes of filtration, making it ideal for industrial applications.

Reliability: Designed for continuous operation, ensuring consistent performance over time.

Applications:

Heavy Industry: Widely used in industries such as mining and metallurgy where large-scale filtration is required.

Wastewater Treatment: Essential in large sewage treatment plants where efficient sludge dewatering is crucial.

Discharge filter presses are essential in various industrial applications, offering different levels of automation and efficiency. Whether it’s a manual discharge filter press for small operations or a fully automated gantry knock discharge filter press for large-scale industrial use, there’s a suitable option for every need. Contact us to understand the advantages and applications of each type, and optimize your filtration processes.

Enterprise Profile:

Since its inception in 2007, Longone has been a key player in the filtration industry, offering innovative dewatering filter presses with advanced technology for diverse performance needs. We specialize in a variety of high-quality filter plates and accessories, designed to tackle even the most complex slurry challenges.

Our expertise is not confined to manufacturing; we extend our services to include consultation and after-sales support, ensuring the right fit for your filtration needs. With a strong presence in industries ranging from mining to chemical processing, Longone is committed to excellence in filtration solutions.