- Home

- >

- Products

- >

- Filter Plate

- >

- Chamber Plate

- >

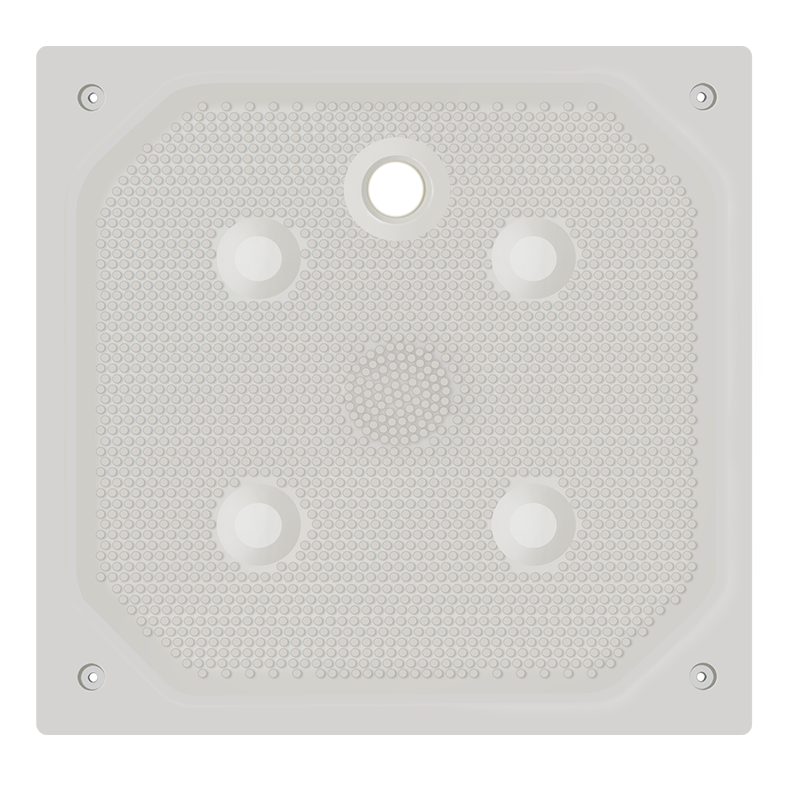

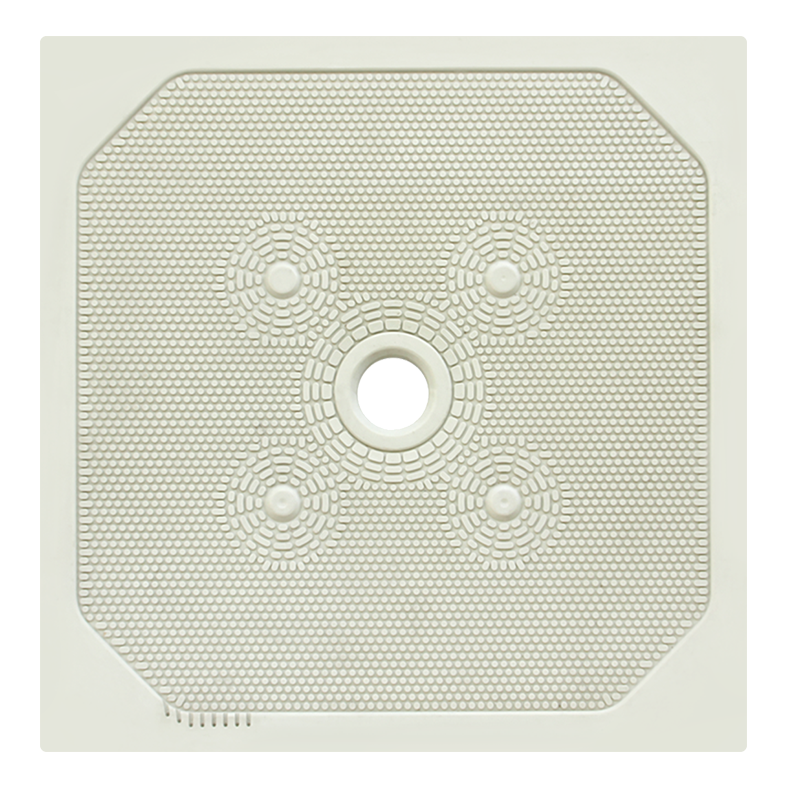

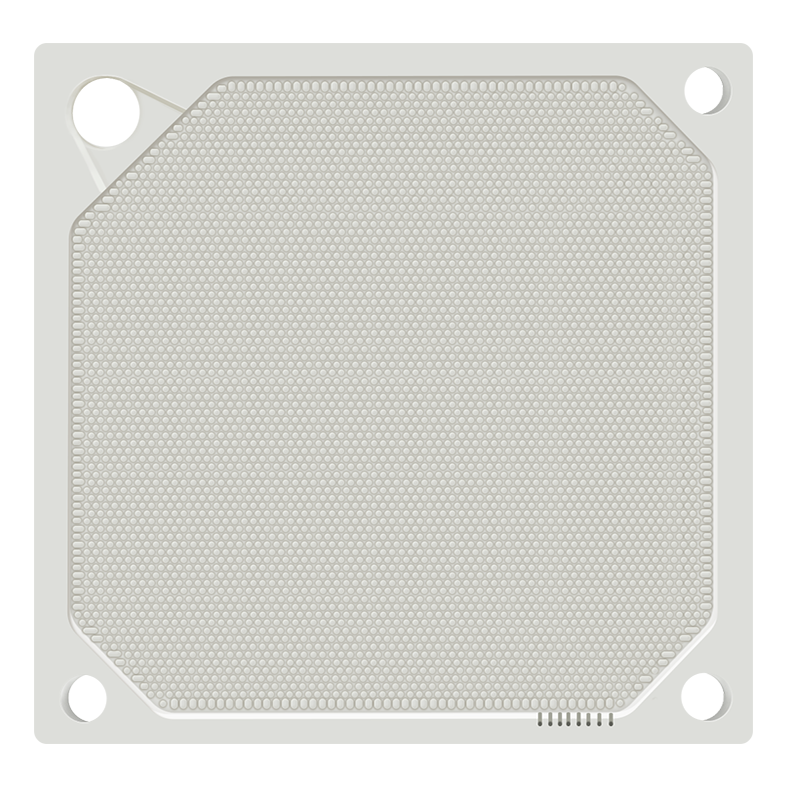

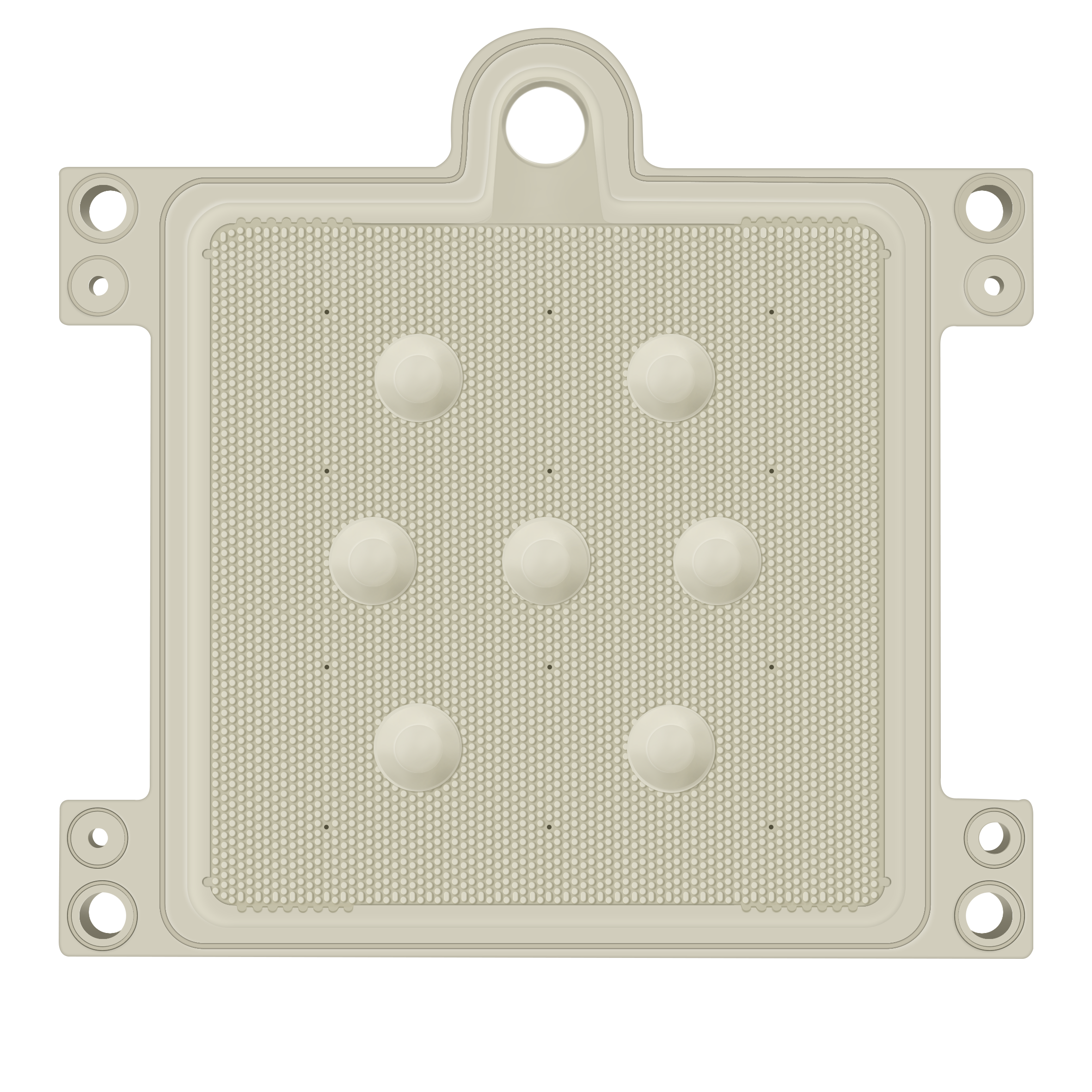

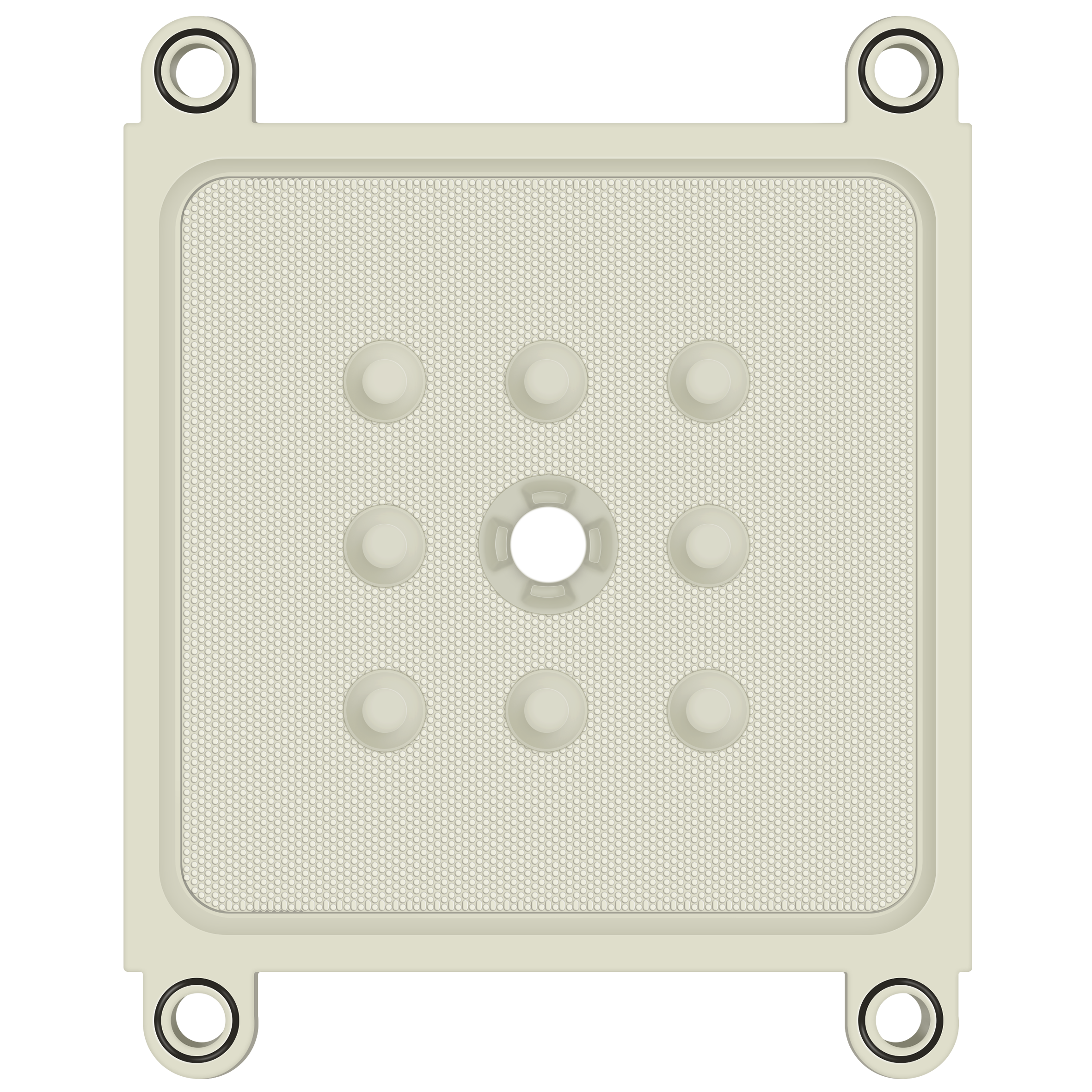

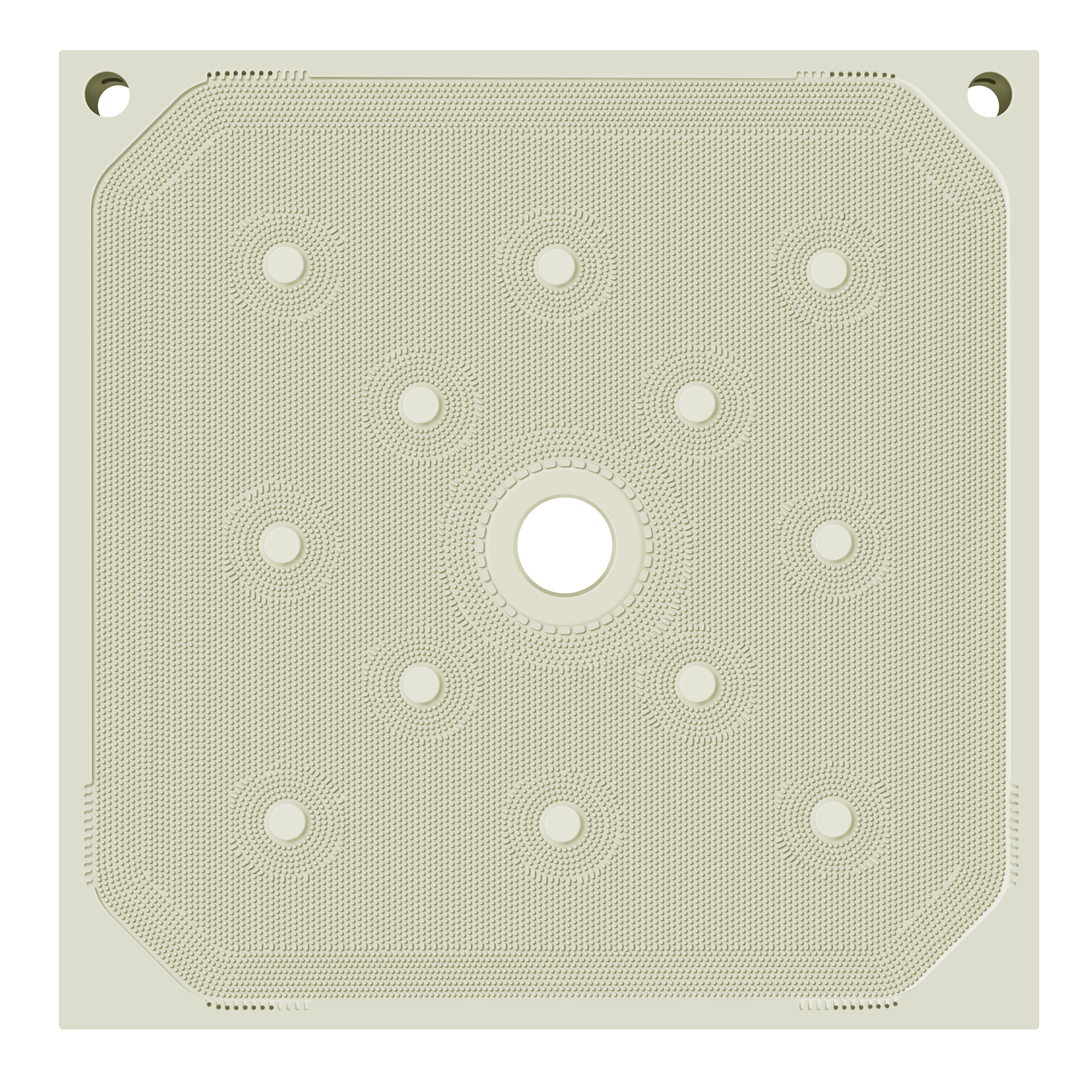

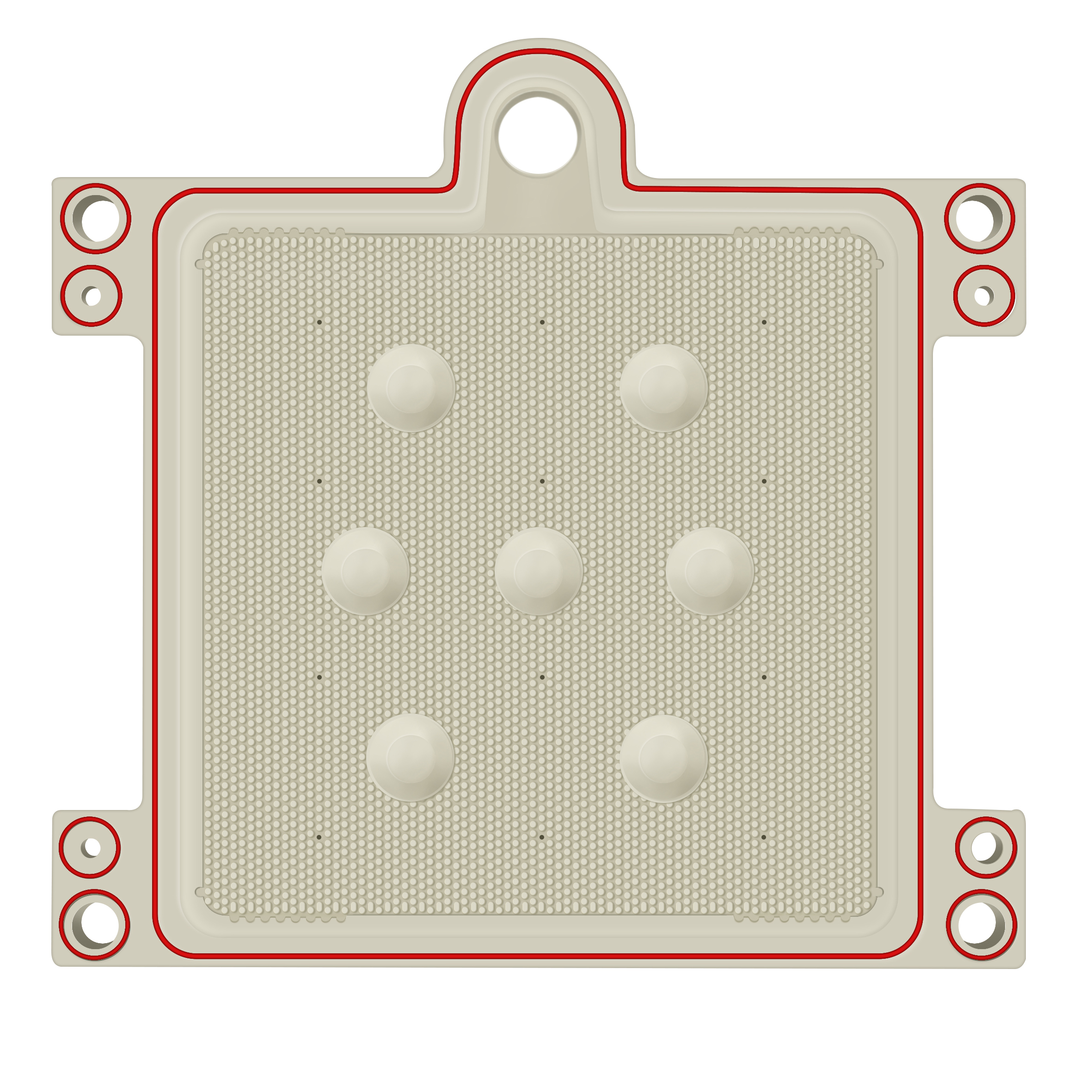

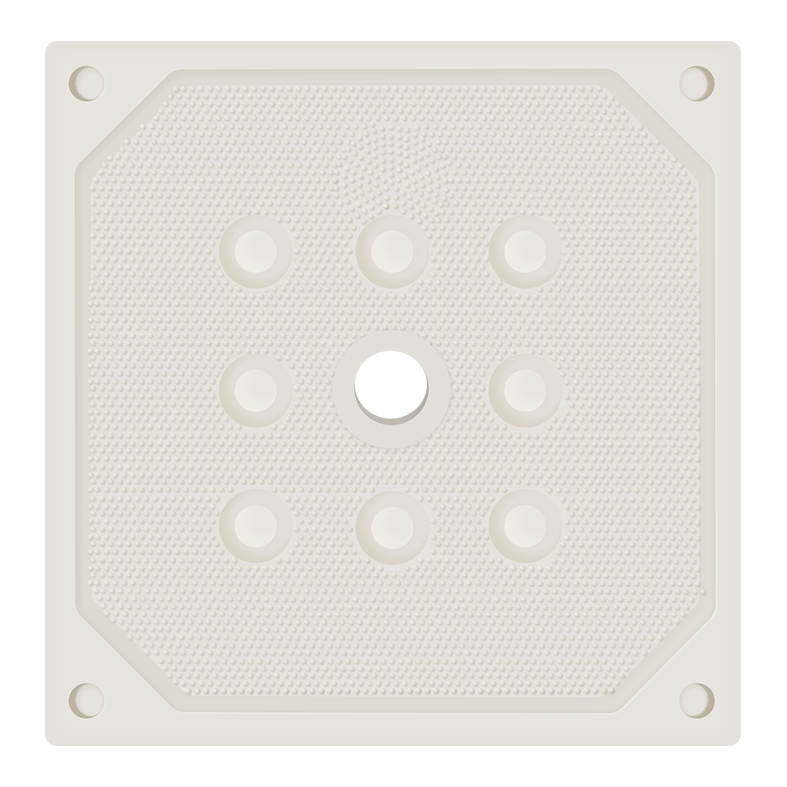

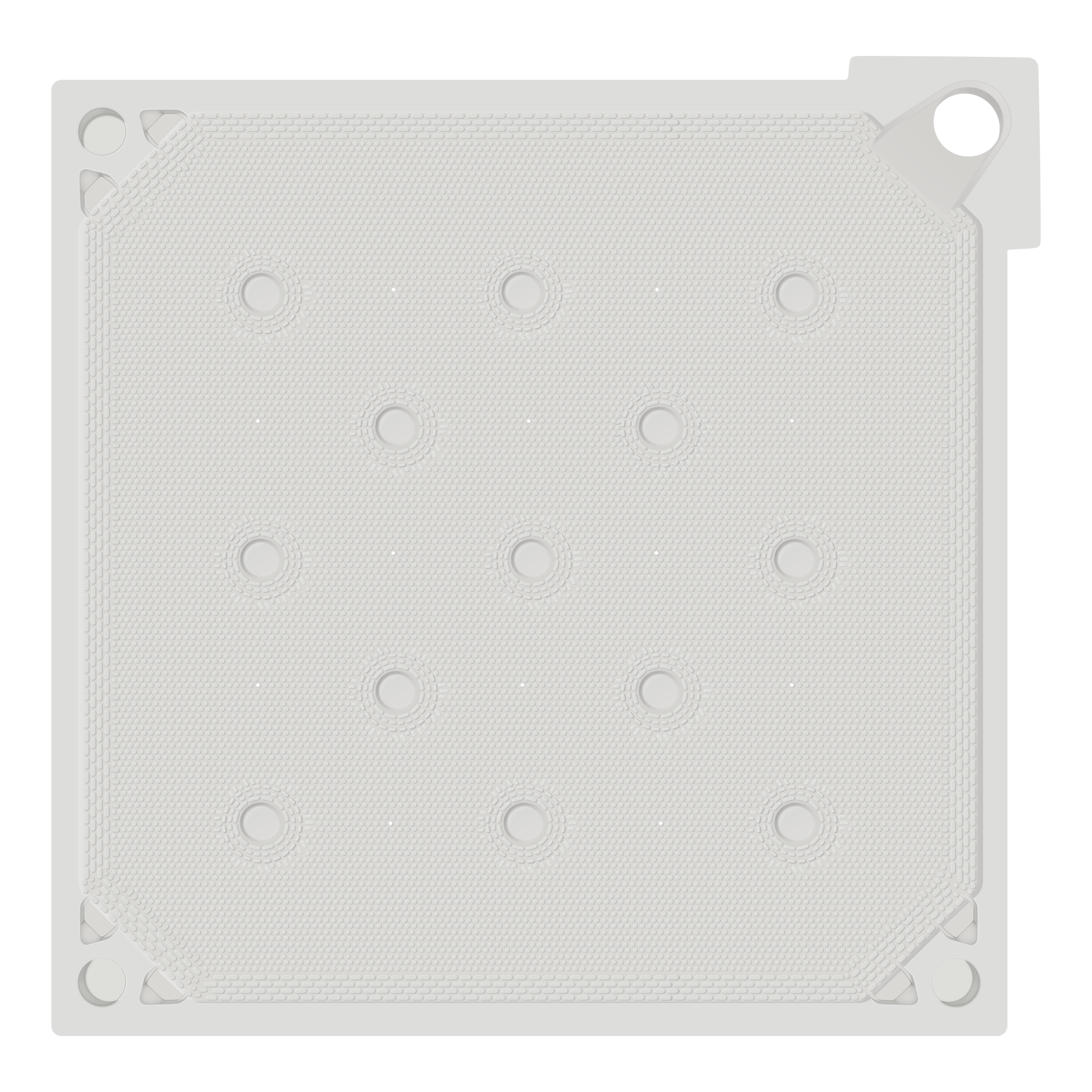

Chamber Plate Product Introduction:

Chamber plates, critical components in filter press systems, are designed to provide superior filtration efficiency and durability. These filter plates are designed to handle a variety of industrial applications, including wastewater treatment, mining, and chemical processing.

Material and Construction:

Chamber plates are typically made from high-quality polypropylene, renowned for its chemical resistance, durability, and lightweight properties. Some chamber filter plates are also constructed from other materials like stainless steel or cast iron, depending on the specific requirements of the application. The solid design of these chamber filter plates ensures longevity and consistent performance under varying pressures and temperatures.

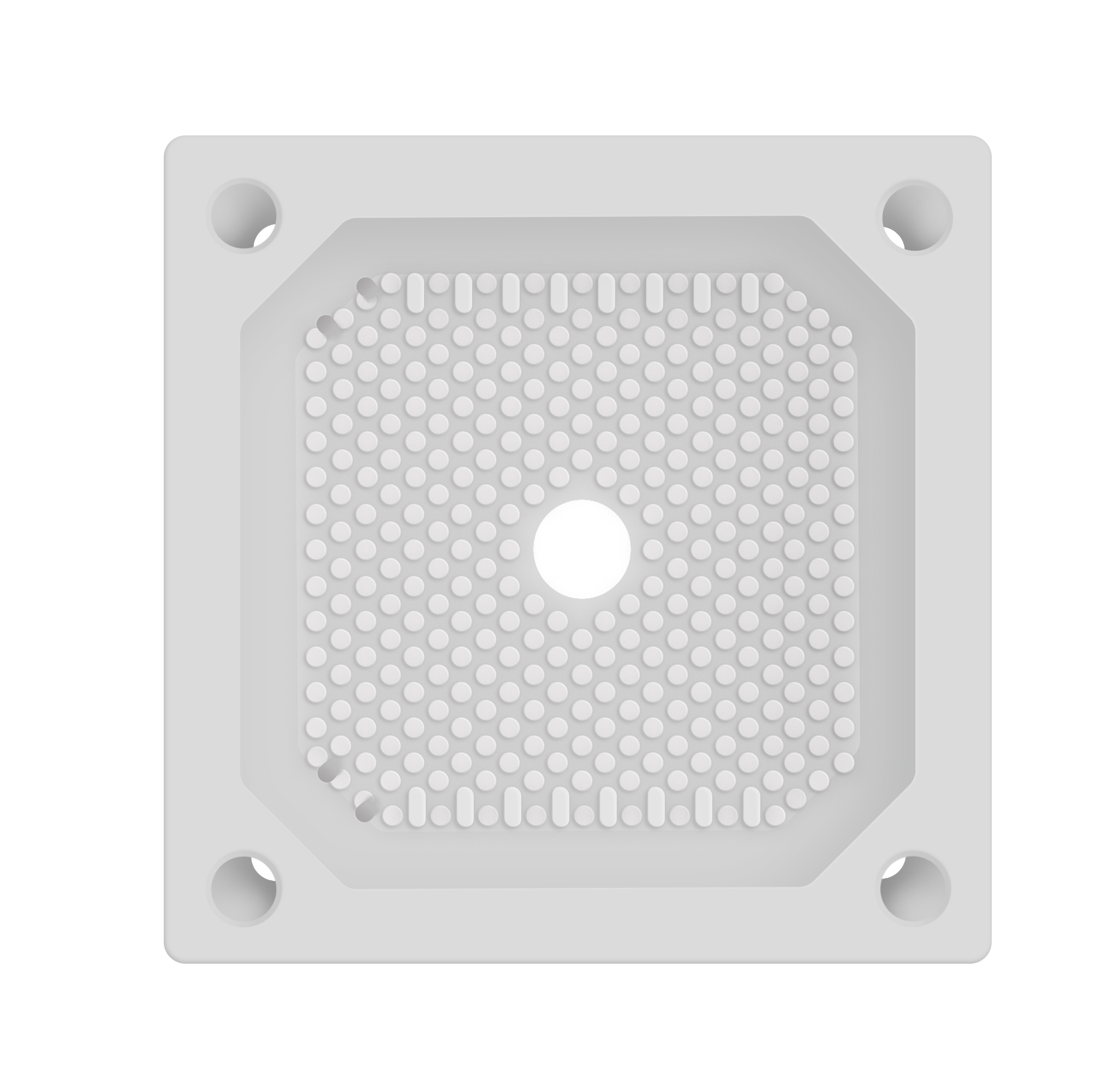

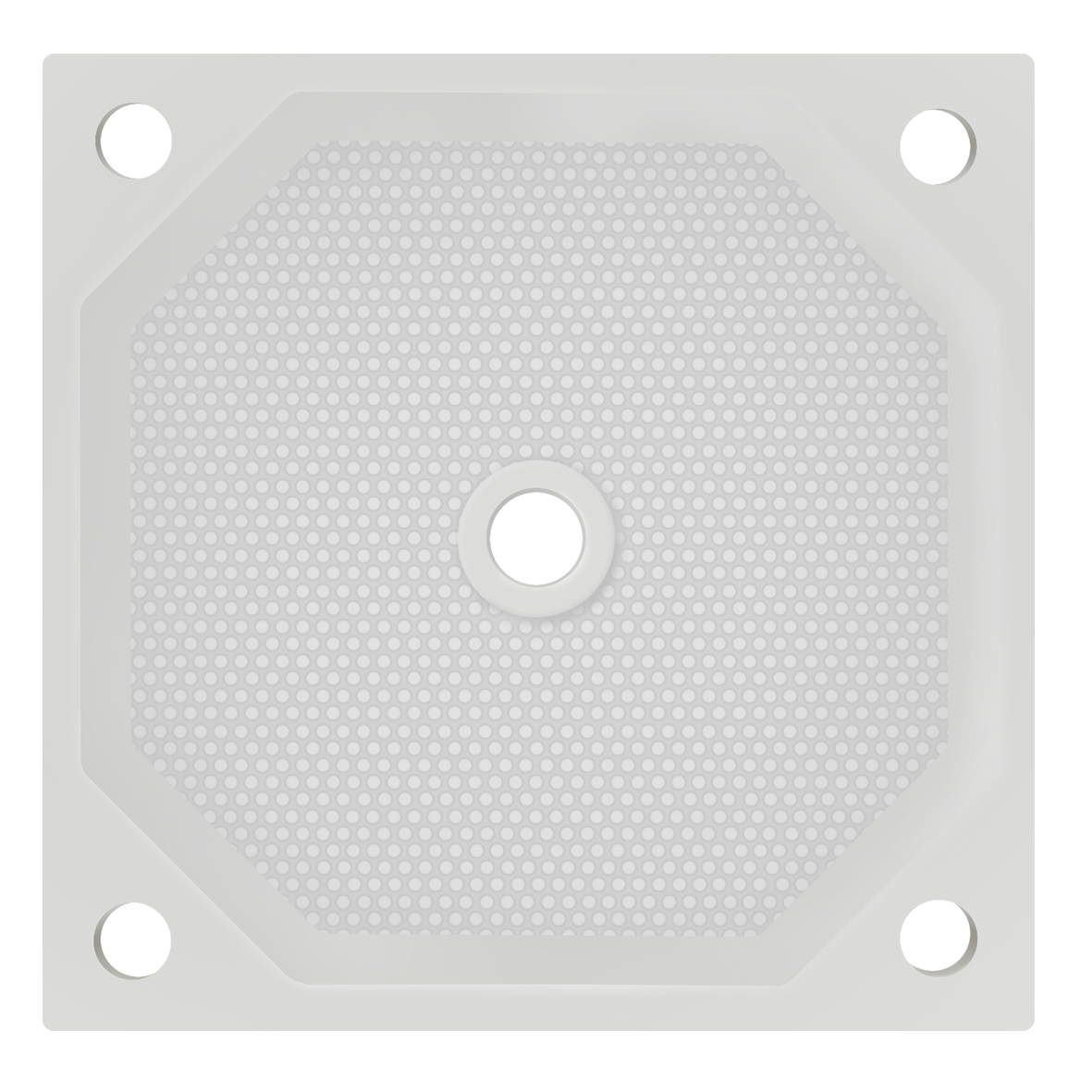

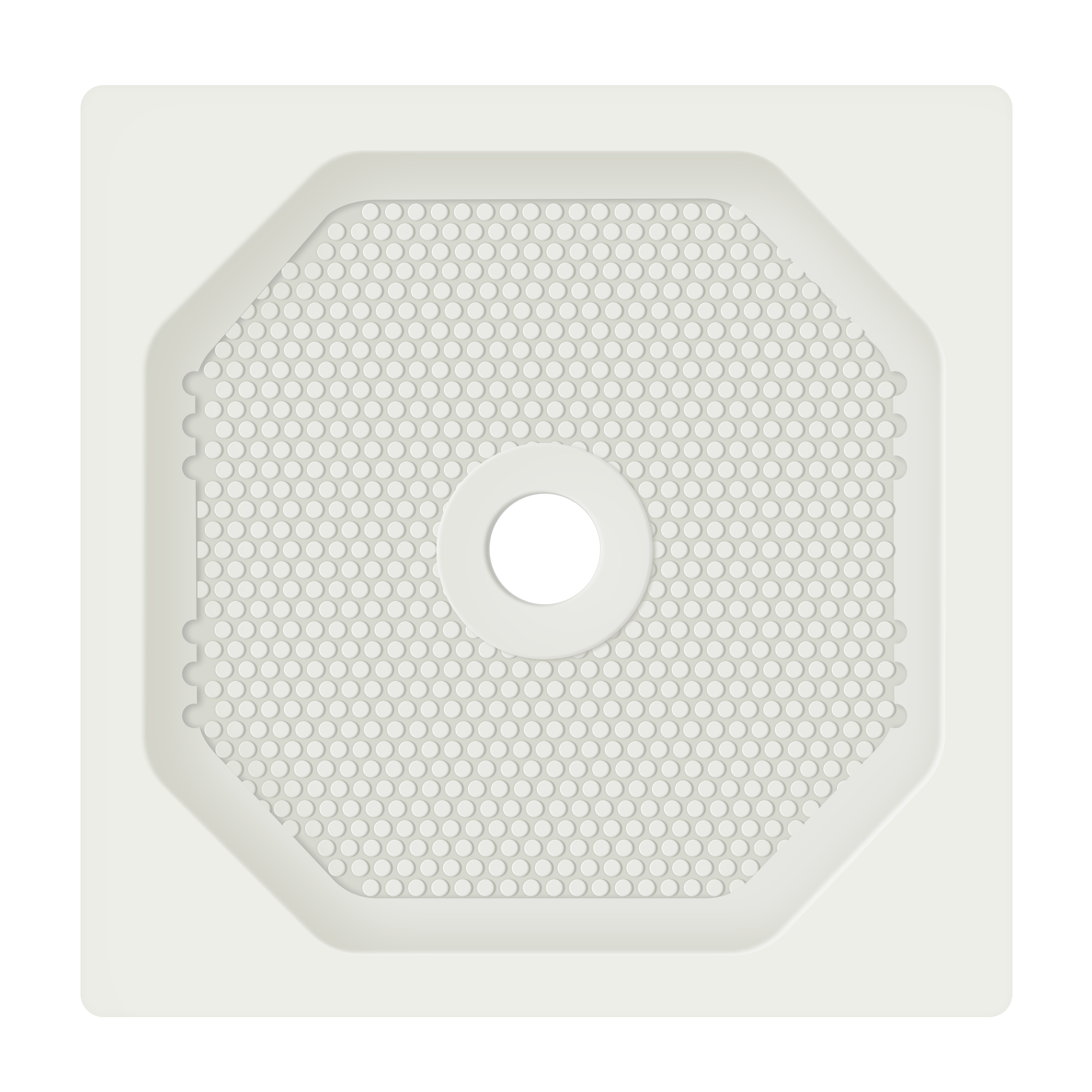

Design and Functionality:

The chamber plate features a recessed cavity that forms a sealed chamber when paired with another filter plate. This design facilitates efficient filtration by creating a chamber for the filtrate to accumulate while the filter cloth captures the solid particles. The chamber plates are equipped with feed and discharge channels, allowing for smooth and uninterrupted flow of the slurry and filtrate.

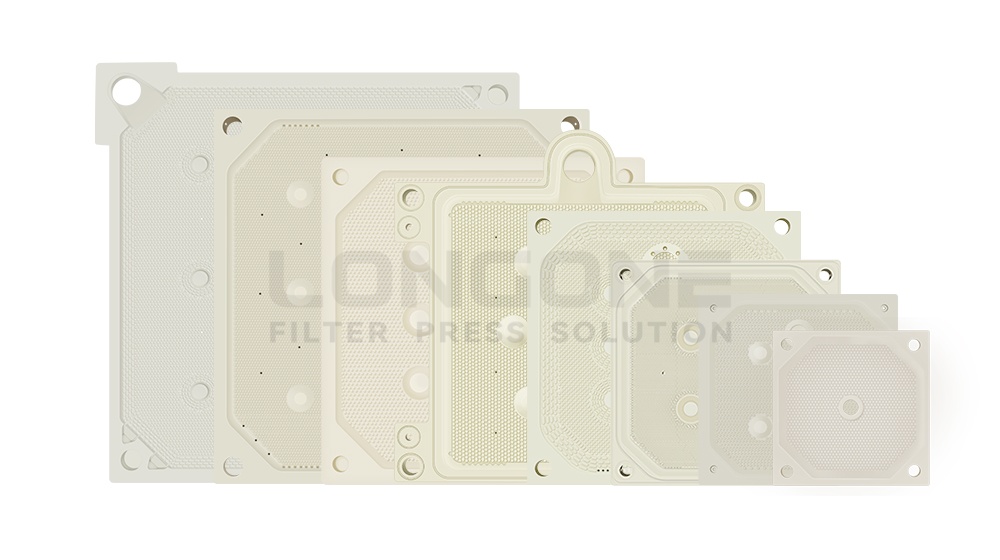

Sizes and Customization:

Chamber plates come in a range of sizes and can be customized to meet the specific needs of different filtration processes. Common sizes include 470 mm, 630 mm, 800 mm, 1000 mm, 1250 mm, 1500 mm, and 2000 mm, but custom dimensions are available upon request. The filter plates can also be tailored with specific feed eye configurations, drainage designs, and cake thicknesses.

Key Features of Chamber Plate:

High Filtration Efficiency:

The design of chamber plates ensures optimal filtration, reducing cycle times and improving overall throughput.

Durability and Chemical Resistance:

Made from high-quality materials like polypropylene, these filter plates resist corrosion and chemical attack.

Ease of Maintenance:

The smooth surfaces and robust construction of chamber plates simplify cleaning and maintenance, reducing downtime and operational costs.

Customizable:

The plate filter is available in various sizes and configurations to match specific process requirements, offering flexibility and adaptability.

Equipment of Filter Plate Processing:

5-Axis Processing Line For Filter Plate: Pioneering automation, Longone’s 5-axis machines redefine precision & efficiency in filter plate production. Unmatched accuracy tackles intricate tasks, ensuring quality & reducing waste.

Longone's Chamber Plate Work Shop:

Longone's Filter Plate :

Classified by SIZES

200mm filter plate 250mm filter plate 400mm filter plate

630mm filter plate 800mm filter plate 1000mm filter plate

1250mm filter plate 1500mm filter plate 2000mm filter plate

Classified by FEEDING TYPES:

Top feeding Center feeding Corner feeding