The global filter press market is undergoing transformative shifts driven by technological advancements, environmental regulations, and evolving industrial demands. As a leading manufacturer of solid-liquid separation solutions, Longone closely monitors these trends to deliver cutting-edge chamber filter presses, membrane filter presses, and fully automatic filter presses applied to diverse sectors such as mining, wastewater treatment, and renewable energy. Below, we analyze the critical developments shaping the automatic filter press industry.

1. Accelerated Adoption of Automation and Intelligent Control Systems:

The demand for automatic filter presses has surged, driven by the need for operational efficiency and reduced labor costs. Advanced PLC systems now dominate high-end models. For instance, hydraulic-driven automatic filter presses with self-cleaning mechanisms and real-time pressure monitoring are becoming industry standards, particularly in mining and chemical processing. These automatic filter press systems minimize human intervention, enhance safety, and optimize filtration cycles by up to 30% compared to traditional manual filter press machine.

Longone's chamber filter presses incorporate Siemens PLC controls and ABB motors, ensuring precise pressure management (up to 60 MPa) and seamless integration with plant-wide automation networks. These innovations of filter press industry are consistent with the trend of global industrialization.

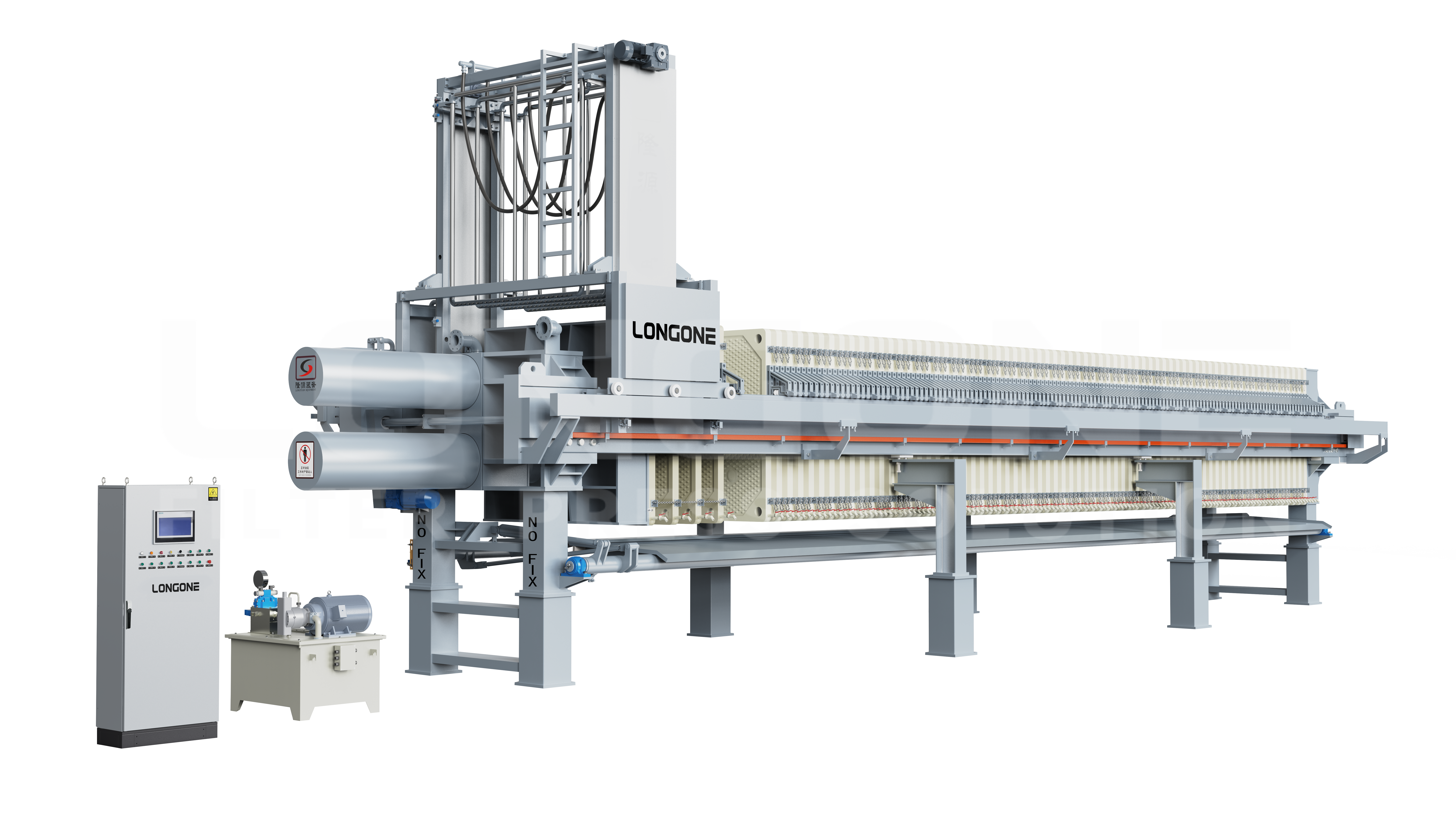

Longone Automatic Filter Press

2. Sustainability-Driven Innovations in Membrane Filter Press Technology:

Environmental regulations, such as the EU's Circular Economy Action Plan, have strengthened their focus on energy-saving and low waste solutions. Membrane filter presses are gaining attention due to their ability to reduce residual moisture in filter cakes by 10–15%, significantly lowering disposal costs and environmental impact. For example, the filter plates made from reinforced polypropylene (PP) or PVDF membranes offer superior corrosion resistance and longevity in harsh environments like acid leaching or coal tailing applications.

Longone Membrane Filter Press

3. Regional Market Expansion and Competitive Landscapes:

The Asia-Pacific region, remains the largest consumer of filter presses, accounting for over 40% of global sales recently. Rapid industrialization, coupled with government investments in wastewater infrastructure, has fueled demand for high-capacity chamber filter presses. Meanwhile, Europe and North America are transitioning toward premium automated systems to replace aging filter presses.

Emerging markets in Africa and Southeast Asia present growth opportunities, particularly for cost-effective, membrane filter presses. Longone's EPC filter press projects in these regions emphasize localized solutions, such as stainless steel chamber plates for tropical climates or compact designs for space-constrained facilities.

Longone Chamber Filter Press

4. Material and Design Breakthroughs:

Material science advancements are redefining filter press durability and performance. Lightweight FRPP (Fiber-Reinforced Polypropylene) plates, with 50% higher tensile strength than conventional PP, are replacing cast iron in corrosive environments. Additionally, chamber filter presses now feature "unseen flow" designs to prevent leakage and volatile organic compound emissions, a critical requirement in pharmaceutical and food industries.

Longone's R&D team has patented hybrid filter plates combining TPE (Thermoplastic Elastomer) membranes with stainless steel frames, achieving 20% longer service life.

5. Challenges and Strategic Responses:

Supply chain disruptions have delayed deliveries industry-wide. To mitigate risks, manufacturers are diversifying suppliers and investing in vertical integration. Longone operates dedicated filter cloth and accessory factories, ensuring 95% in-house production of critical parts.

The global automatic filter press market is evolving rapidly, with automation, sustainability, and regional customization. As industries prioritize efficiency and regulatory compliance, solutions like automatic chamber filter presses and membrane filter presses will dominate future investments. Longone remains committed to innovation, leveraging its ISO-certified R&D center and 50+ patents to deliver tailored, sustainable filtration systems.

Longone Chamber Filter Press

Longone Membrane Filter Press