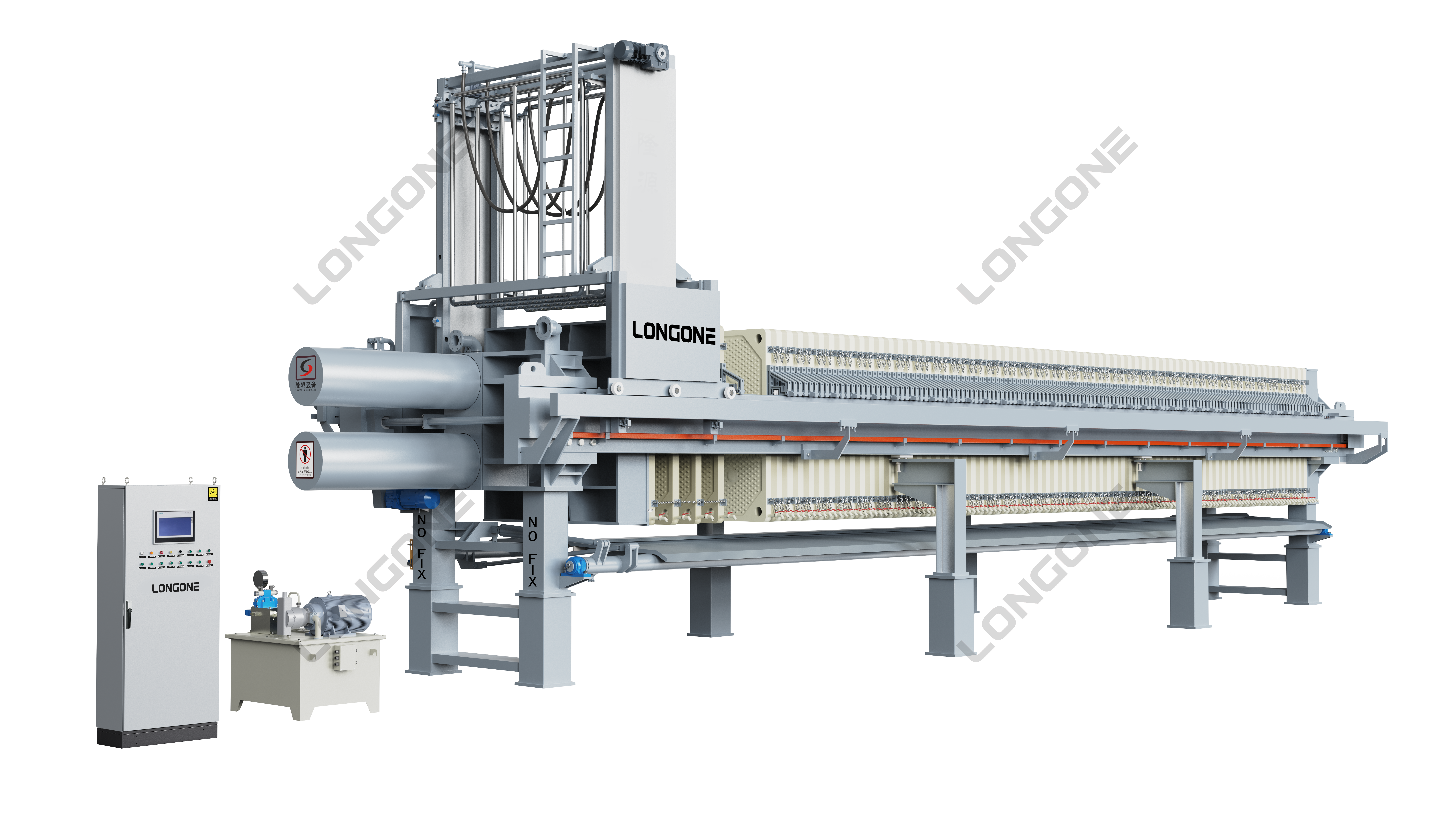

What is an Automatic Washing Filter Press?

In modern industrial operations, filtration plays a pivotal role in maintaining the quality and purity of various fluids. Among the array of filtration technologies, the automatic washing filter press stands out for its high efficiency and reliability. A critical feature that enhances its performance is the integration of an advanced automatic water washing system.

Overview of the System

The automatic water washing system for filter presses is an all-encompassing solution engineered to automate the cleaning of filter cloths. This not only boosts filtering performance but also prolongs the filter cloth's service life. The system merges precision engineering with state-of-the-art automation technology to achieve outstanding results.

System Components

- Water Washing Unit: This unit comprises high-pressure nozzles, water pipes, and a robust pump. The nozzles are specifically designed to generate a concentrated jet of water, ensuring a thorough and deep cleaning of the filter cloth. The use of high-pressure water aids in the effective removal of fine particulates that may otherwise clog the filter media.

- Drive Mechanism: The drive mechanism facilitates the movement of the water washing unit across the entire surface of the filter cloth. It includes an electric motor, precision-engineered gears, and bearings, all of which ensure smooth and consistent operation. This precision ensures that every section of the filter cloth is cleaned uniformly, preventing the formation of untreated sections that could compromise filtration efficiency.

- Intelligent Control System: Central to the automatic water washing system is an intelligent control system. This advanced control system monitors performance metrics, processes sensor data, and manages the operation of the water washing unit and drive mechanism. The control system's adaptability allows it to respond to varying operational conditions, maintaining optimal performance.

Working Principle

- Monitoring and Detection: The intelligent control system utilizes an array of sensors to continuously monitor the condition of the filter cloth. These sensors detect levels of contamination and build-up, providing real-time data on the cloth's cleanliness and the filtration process's overall efficiency. Advanced sensors, such as optical or ultrasonic sensors, may be used to assess the particulate accumulation on the filter cloth with high accuracy.

- Initiation of the Washing Cycle: Upon reaching a preset contamination threshold, the control system initiates the washing cycle automatically. This threshold can be adjusted based on specific operational requirements, ensuring flexibility in maintaining the filter cloth's cleanliness.

- Water Washing Operation: During the washing cycle, the pump activates to deliver high-pressure water to the nozzles. These nozzles emit a concentrated water jet that penetrates deep into the filter cloth, dislodging and removing trapped contaminants. The drive mechanism moves the washing unit systematically across the cloth, guaranteeing comprehensive coverage. The use of high-pressure water jets is particularly effective in breaking down and washing away stubborn residues that may adhere to the cloth.

- Adjustment and Optimization: Throughout the washing process, the control system continually assesses operational parameters such as water pressure, nozzle speed, and the movement pattern of the washing unit. It adjusts these parameters dynamically to optimize cleaning efficiency, ensuring that the filter cloth is thoroughly cleaned while minimizing water usage and energy consumption.

- Completion and Post-Cycle Monitoring: After completing the washing cycle, the control system deactivates the pump and drive mechanism. It then resumes monitoring the filter cloth's condition, ready to initiate another cleaning cycle if necessary. This continuous monitoring ensures that the filter cloth remains in optimal condition, thereby enhancing the overall filtration process's reliability and effectiveness.

Technical Features and Benefits

- Enhanced Efficiency: The focused water jet and comprehensive coverage ensure that contaminants are swiftly and effectively removed. The system's high-pressure cleaning capability is critical in maintaining the filter cloth's permeability, thus ensuring consistent filtration performance.

- Automation and Convenience: The intelligent control system significantly reduces the need for manual intervention, leading to substantial savings in labor and time. Automation also minimizes the risk of human error, ensuring a consistent and reliable cleaning process.

- Optimization and Flexibility: The system's capability to adjust operational parameters during the washing cycle allows for optimal performance tailored to specific conditions and requirements. This flexibility ensures that the filter press can handle a wide range of filtration challenges effectively.

- Prolonged Filter Cloth Life: Regular, thorough cleaning prevents the accumulation of debris and contaminants that can degrade the filter cloth over time. By maintaining the filter cloth in good condition, the system extends its lifespan and reduces the need for frequent replacements, leading to cost savings.

- Improved Filtration Performance: A clean filter cloth ensures higher filtration efficiency, resulting in superior quality of the filtered product. Maintaining optimal cloth cleanliness is crucial in industries where filtration precision is paramount, such as in pharmaceuticals, chemicals, and food processing.

- Energy and Resource Efficiency: Advanced systems are designed to minimize water and energy consumption, making them environmentally friendly. Efficient use of resources not only reduces operational costs but also aligns with sustainable practices in industrial operations.

- Maintenance and Operational Reliability: The system's automation and intelligent monitoring reduce maintenance needs and downtime, ensuring continuous and reliable operation of the filtration process. Regular self-diagnostics and predictive maintenance features can preemptively address potential issues, further enhancing system reliability.